Kaizen Continuous Improvement

We help you maximize utilization of resources through elimination of waste & losses and Reduce Business throughput time by leveraging proven strategies of Lean Kaizen.

Lean Kaizen is all about doing more with Less..

Lean Kaizen is a way of seeing and managing the way work is done in a manner that allows you to identify and eliminate waste. It is not a concept – a way of thinking, it is not a tool…It’s a philosophy, a culture that MUST be practiced throughout the organization, day in and day out.

In today’s fast paced world, speed and agility of process is a critical factor that enables quick delivery to customers. Lean Kaizen is a business approach based on the fundamental goal of eliminating waste and maximizing flow. A lean organization is one that fully understands, communicates, implements and sustains lean concepts seamlessly throughout all operational and functional areas. The lean process is one in which all employees of the company are involved and obessed about eliminating waste.

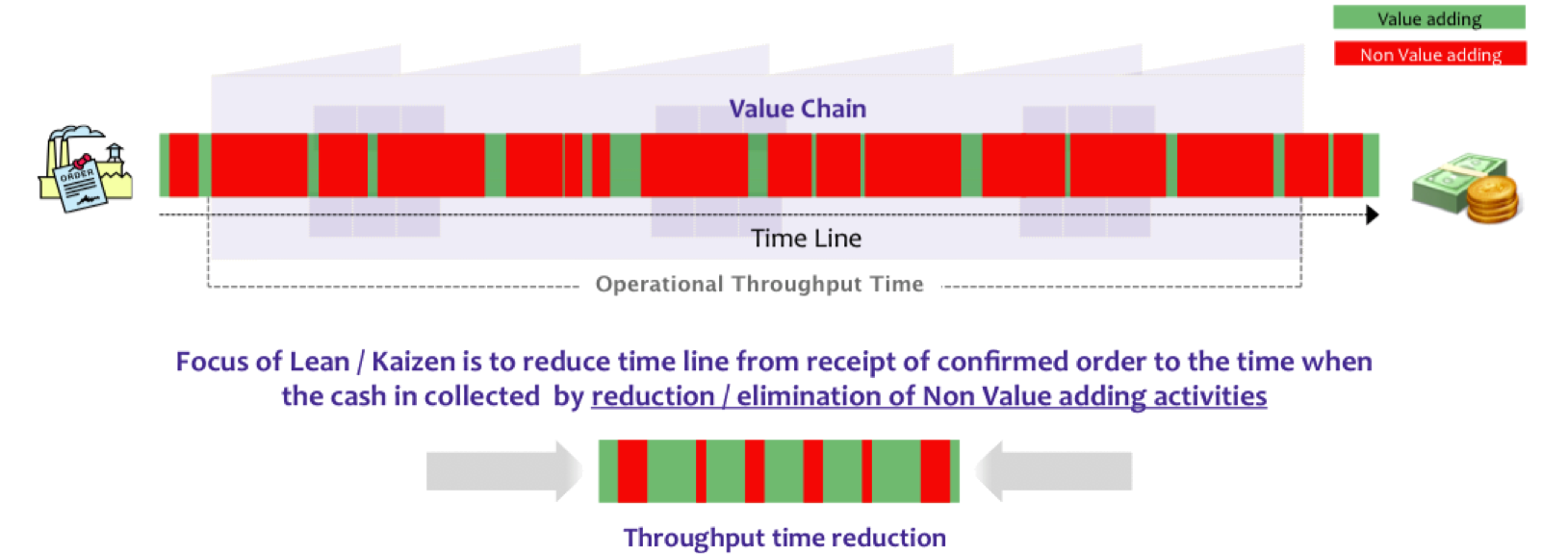

Focus of Lean Kaizen is to continuously reduce Business Throughput time by identify, reducing and eliminating MUDA (Waste) .The core idea is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources. To accomplish this, lean kaizen thinking changes the focus of management from optimizing separate technologies, assets, and vertical departments to optimizing the flow of products and services through entire value streams that flow horizontally across technologies, assets, and departments to customers

In Lean there are seven major types of non-value-adding activities in business or manufacturing processes.

Overproduction. Producing items earlier or in greater quantities than needed by the customer. Producing earlier or more than is needed generates other wastes, such as overstaffing, storage, and transportation costs because of excess inventory. Inventory can be physical inventory or a queue of information.

Waiting: Workers merely serving as watch persons for an automated machine, or having to stand around waiting for the next processing step, tool, supply, part, etc., or just plain having no work because of no stock, lot processing delays, equipment downtime, and capacity bottlenecks.

Transportation or conveyance: Moving work in process (WIP) from place to place in a process, even if it is only a short distance. Or having to move materials, parts, or finished goods into or out of storage or between processes.

Overprocessing or incorrect processing: Taking unneeded steps to process the parts. Inefficiently processing due to poor tool and product design, causing unnecessary motion and producing defects. Waste is generated when providing higher quality products than is necessary. At times extra “work” is done to fill excess time rather than spend it waiting.

Excess inventory: Excess raw material, WIP, or finished goods causing longer lead times, obsolescence, damaged goods, transportation and storage costs, and delay. Also, extra inventory hides problems such as production imbalances, late deliveries from suppliers, defects, equipment downtime, and long setup times.

Unnecessary movement: Any motion employees have to perform during the course of their work other than adding value to the part, such as reaching for, looking for, or stacking parts, tools, etc. Also, walking is waste.

Defects: Production of defective parts or correction. Repairing of rework, scrap, replacement production, and inspection means wasteful handling, time, and effort.

Unused employee creativity: Losing time, ideas, skills, improvements, and learning opportunities by not engaging or listening to your employees

Long term objective of Lean Management & Kaizen is to create a learning organization in which problems are constantly surfaced and team associates are equipped with the tools to eliminate waste. . Lean Kaizen is a longer term strategy for developing lean value streams and ultimately a lean enterprise. One useful tool for guiding improvements based on a carefully thought-through plan is value stream mapping.

Eliminating waste along entire value streams, instead of at isolated points, creates processes that need less human effort, less space, less capital, and less time to make products and services at far less costs and with much fewer defects, compared with traditional business systems. Companies are able to respond to changing customer desires with high variety, high quality, low cost, and with very fast throughput times. Also, information management becomes much simpler and more accurate

A good place for any company to begin the journey to lean Kaizen is to create continuous flow wherever applicable in its core manufacturing and service processes. Flow is at the heart of the lean message that shortening the elapsed time from raw materials to finished goods (or services) will lead to the best quality, lowest cost, and shortest delivery time. Flow also tends to force the implementation of a lot of the other lean tools and philosophies such as preventative maintenance and built-in quality (jidoka). A commonly used lean expression is that lowering the “water level” of inventory exposes problems (like rocks in the water) and you have to deal with the problems or sink. Creating flow, whether of materials or of information, lowers the water level and exposes inefficiencies that demand immediate solutions. Everyone concerned is motivated to fix the problems and inefficiencies because the process will shut down if they don’t. Traditional business processes, in contrast, have the capacity to hide vast inefficiencies without anyone noticing—people just assume that a typical process takes days or weeks to complete. They don’t realize that a lean process might accomplish the same thing in a matter of hours or even minutes

Flow means that when your customer places an order, this triggers the process of obtaining the raw materials needed just for that customer’s order. The raw materials then flow immediately to supplier plants, where workers immediately fill the order with components, which flow immediately to a plant, where workers assemble the order, and then the completed order flows immediately to the customer. The whole process should take a few hours or days, rather than a few weeks or months.

An example of this is the fact that Toyota engineers new vehicles in Japan in less than one year. Their competitors take over two years. The reason is that Toyota’s engineering work is organized into a flow, and efforts are constantly made to reduce waste in this flow. Its engineering work, design decisions, prototype construction, and tool construction seamlessly flow and “communicate” from the beginning to the end of the vehicle design process. No one produces anything before it is needed by the next person or step in the process.

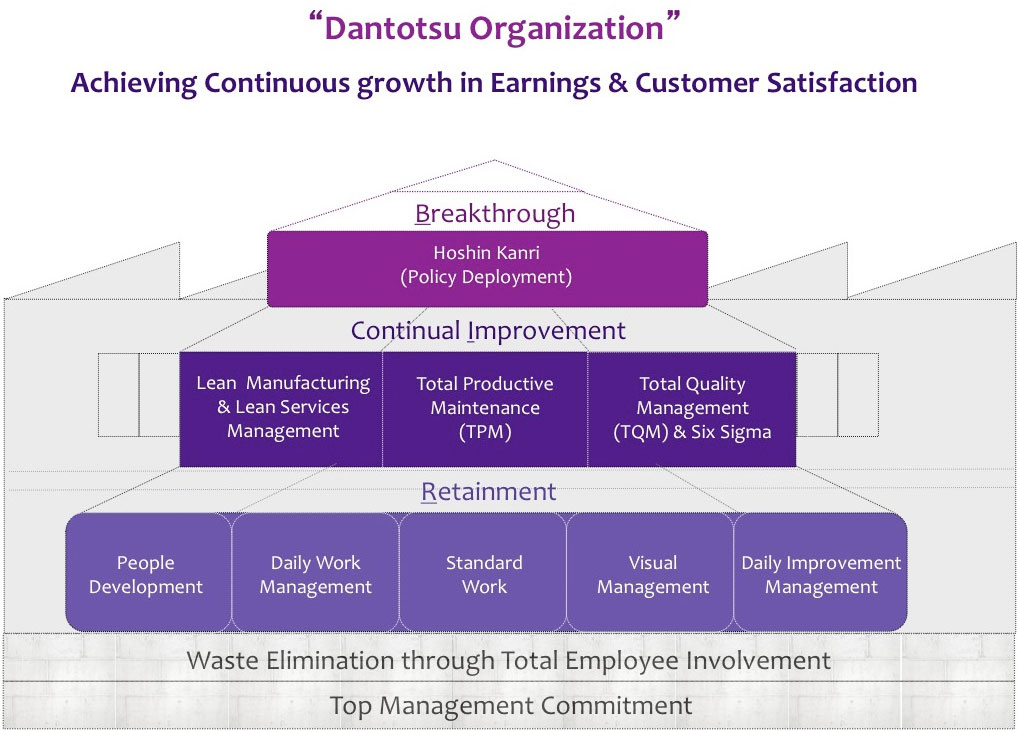

We help our client companies to Implement Lean Kaizen in a systematic manner and focusing on the entire value stream for process optimization through waste elimination. Our Consulting services can help you in implementing various tools in Lean manufacturing through our RIB Model.

Our Unique RIB Model focuses on 3 Main Tools of Improvement: Lean Management, Total Productive Maintenance & Total Quality Management.