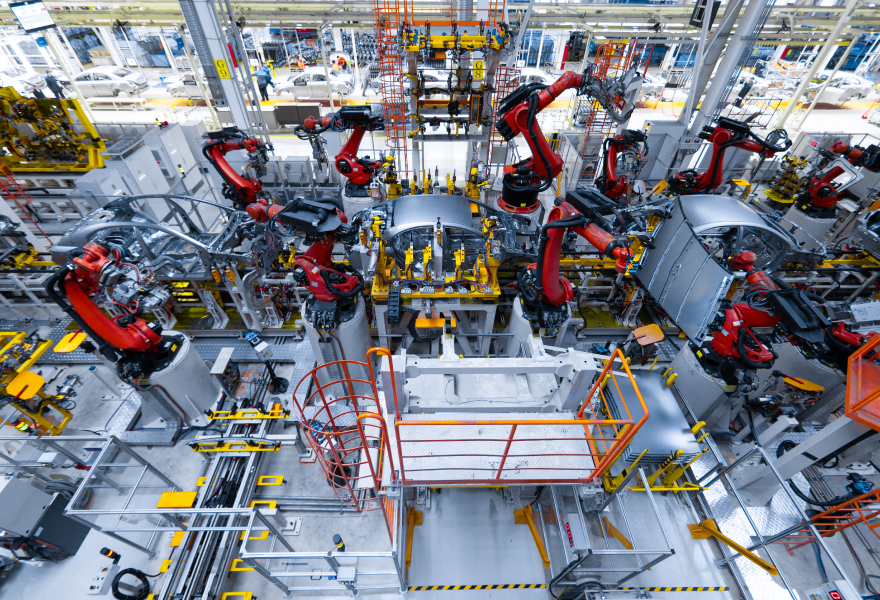

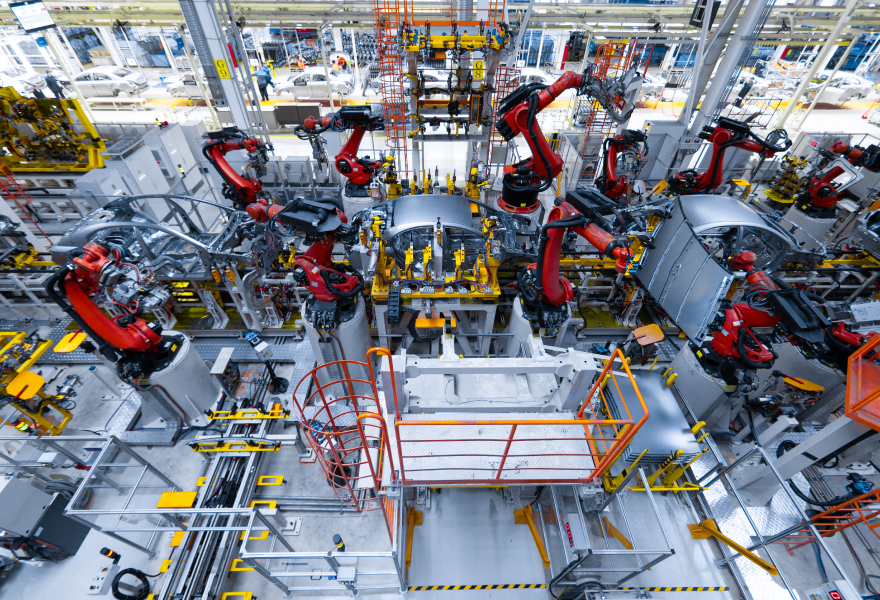

In the evolving landscape of maintenance, the emphasis is shifting from merely resolving breakdowns to predicting and preventing them. To effectively implement a model based on Total Productive Maintenance (TPM) principles, we need to design predictive and planned approaches that will optimize spare parts stock management, reduce equipment downtime, and maximize efficiency. Ribcon’s TPM consulting services empower businesses to boost efficiency, reduce costs and improve OEE.

What is TPM? Total Productive Maintenance or TPM is a comprehensive approach to improve efficiency, productivity and reliability of the equipment throughout its entire lifecycle. To maximise the equipment effectiveness, TPM aims at eliminating 16 Major losses, which obstruct production efficiency.

Our Total Productive Maintenance consulting is directed towards the ultimate goal of zero equipment breakdown and zero product defects, which in turn results in improved utilization of production assets and plant capacity. Ribcon’s TPM consulting services also includes designing and installing equipment that needs little or no maintenance and setting up processes for quickly repairing equipment after breakdowns occur.

With our extensive experience in Total Productive Management consulting for various companies in Kenya and India, we are recognized as one of the leading TPM consultants in India today. If you are seeking TPM consultancy services, please feel free to contact Ribcon, the leading TPM consulting company in India.

Downtimes reduction including breakdown and change over time

Speed loss reduction

Material loss reduction

Overall equipment effectiveness improvement

Measure & quantity Major OEE losses. Identify chronic losses and develop problem solving capabilities with systematic approach to reduce OEE losses.

Create equipment competent operators to reduce forced deterioration of equipment and reduce breakdowns.

Effective maintenance planning & scheduling through predictive, time & condition based techniques to improve maintenance team productivity, Spare Parts Management, Failure analysis and prevention of recurrence.

Enhance technical and TPM knowledge of operators and maintenance team and Build internal capacity to lead and implement TPM.

Improve the equipment condition to achieve zero defects by checking and measuring equipment conditions in time-series to prevent defects.

Our expert TPM consultants conduct a one-week deep dive assessment to identify opportunities and priorities for improvement in Overall Equipment Effectiveness (OEE), through Gemba observations, data analysis and meeting with all key stakeholders and estimate improvement targets and financial benefits of implementing TPM.

Customised TPM training including classroom and shop floor training on key TPM pillars and tools to address the major OEE losses identified during assessment. Ribcon’s trained TPM expert ensures that your teams develop the right mindset, knowledge, and skills to maximize the benefits of TPM implementation.

TPM is implemented through ‘Learn by Doing’ 5 Day TPM workshop using systematic methodology to TPM pillars and tools identified during assessment. This workshop is aimed at executing rapid improvement work on the shop floor with cross functional teams for effective results. Implementation is amongst the most crucial aspects in Ribcon’s TPM approach.

Our team of TPM experts assists in establishing a robust TPM management and sustenance structure within your organization through TPM committees. This framework is designed to drive and review TPM implementation, track progress, achieve desired results, and sustain improvements.

Clients

Industries

Successful TPM projects

Return on investment

Our customized TPM implementation approach focuses on identification of major OEE losses and selecting key TPM pillars to address major losses. The expertise and skills of Ribcon’s TPM consultants ensures that your teams are well-equipped to maximize the benefits of TPM implementation.

Our TPM consultants engage at all levels and functions in an organization to maximize overall production efficiency. Ribcon’s TPM consultants in India tune up existing processes and equipment by reducing downtimes, mistakes and accidents.

A vital part of our TPM consulting (Total Productive Maintenance) is to train workers to take care of the equipment with which they work. Our TPM consultants in India work with your team to train them on preventive maintenance, mistake-proofing equipment, to eliminate product defects and to make maintenance easier.

Combining TPM pillars and tools with Ribcon’s TPM experts helps organisations reduce breakdowns by 50% and improve OEE by 25%.

We are global TPM consultants offering TPM consultancy services worldwide in more than 20 countries.

Integrating TPM with digital capabilities can help companies eliminate losses, maximise equipment efficiency, save more money and ensure higher performance of their operations. We provide expertise and tools to identify improvement opportunities and enhance operational excellence.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!