SMED, or Single-Minute Exchange of Die, also known as Quick Changeover or Setup Time Reduction, is a powerful Lean manufacturing technique designed to minimize equipment setup and changeover times. The term “single-minute” refers to achieving changeovers in a single-digit number of minutes — ideally under ten.

Reducing setup and changeover times is critical for enhancing operational flexibility, production responsiveness, and overall equipment effectiveness (OEE). Through SMED, organizations can achieve faster transitions between products or batches, enabling smaller lot sizes, improved flow, and reduced downtime.

Our hands-on SMED training helps manufacturing teams drastically reduce changeover times and boost production efficiency using real-world, data-driven methods. Through a blend of classroom learning and on-the-floor coaching, participants learn how to Conduct detailed cycle time and setup time studies, Identify and eliminate waste in setup and changeover activities, Differentiate internal and external setup tasks, Systematically convert internal activities to external ones and Implement a standardized changeover process that sustains improvement

By streamlining and reducing the time taken for these activities, teams can significantly minimize non-productive time, increase equipment utilization, and effectively support Just-In-Time (JIT) manufacturing.

Step 1: Study & Identify Tasks

Step 2: Separate Internal and External tasks

Step 3: Convert Internal tasks into External tasks

Step 4: Reduce Internal time

Step 5: Reduce External Time

SMED Case Study

Walk through each step of the SMED process and its resulting impact on efficiency, downtime, and production flow covering following improvements:

Actual changeover study on shop floor

Conduct actual changeover study of selected fast moving product and high frequency changeover

Standardise and Sustain

Improvements done must be sustained by establishing standards and tracking actual results vs standards. Any deviation from standards to be analysed and corrective actions to be taken.

SMED trainings conducted

successful SMED projects

participants trained

Sharing of experience and case studies with practical application of SMED by Lean experts, worked across various industries and sectors.

The training program is tailored to align with organisation goals, by initial discussions with key stakeholders.

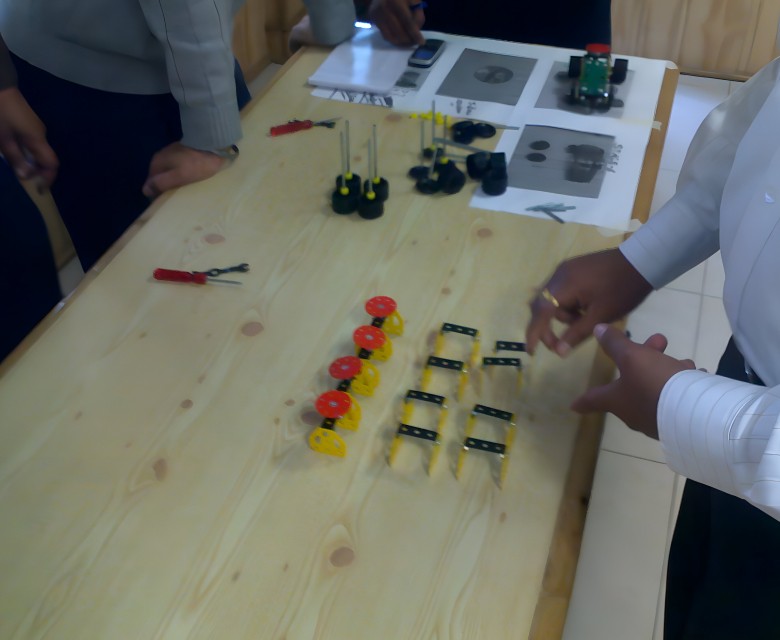

Practical learning through group activities, case studies, and simulation games, ensuring an engaging and hands-on experience at both classroom and shop floor of implementing SMED.

Train-the-Trainer program is led by a highly experienced trainer and Lean expert to enable internal capacity building and empower teams for ongoing success.

Flexible online and off-site SMED training programs designed to suit the needs of the organisation.

Participants will get certification only after the submission of defined SMED projects and results delivered, ensuring target outcomes are achieved for each project.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!