A Milk Run is a lean logistics strategy designed to streamline transportation and inventory management. Instead of multiple suppliers dispatching individual trucks, a single vehicle follows a fixed, scheduled route to collect or deliver goods from multiple suppliers or customers.

Originally developed by Toyota, the Milk Run system helps maintain low inventory levels while ensuring high delivery frequency—typically 4 to 6 shipments per day. By standardizing routes, optimizing truck capacity, and reducing redundant trips, Milk Run logistics significantly lower transportation costs and enhance supply chain efficiency.

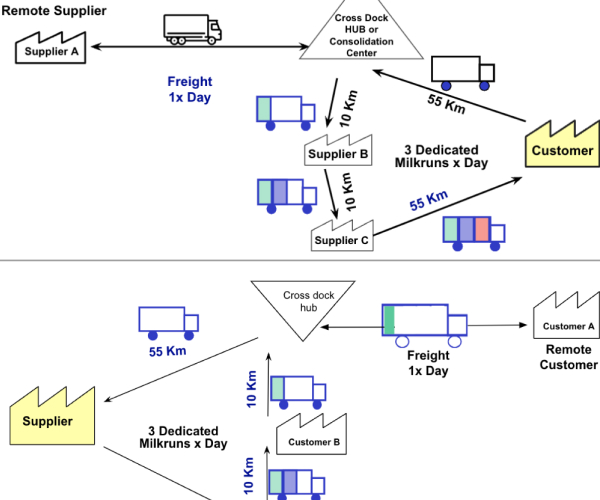

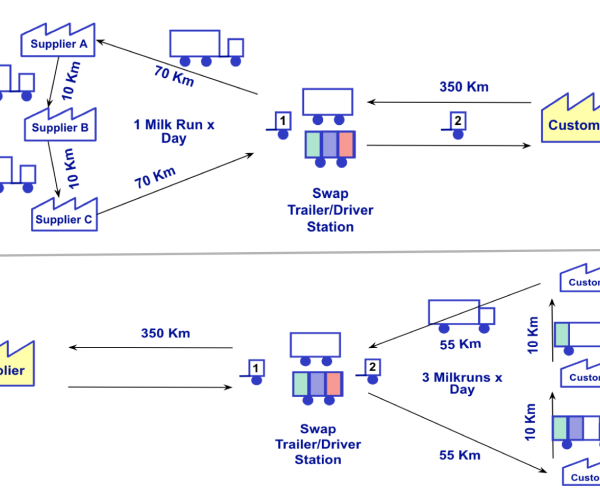

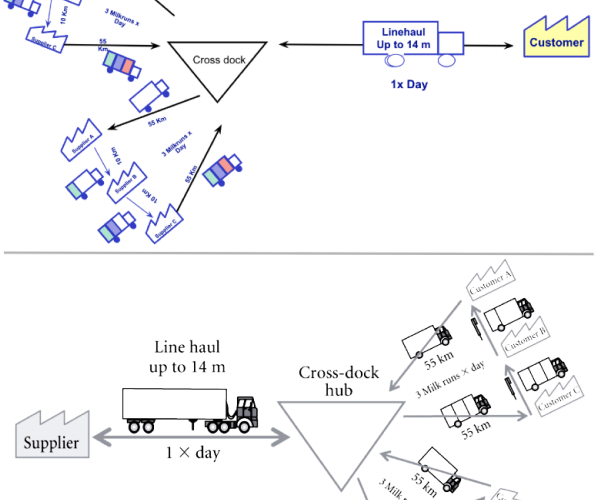

Milk Run logistics can be adapted to suit different distances, supplier locations, and supply chain requirements. Depending on the geographic spread and operational goals, companies can implement various types of Milk Runs—ranging from short-range local loops to long-haul consolidated routes. Each type is designed to optimize efficiency, reduce transport costs, and maintain consistent delivery flow.

Reduction in transport cost

Reduction in inventory

Space saving

Capture inventory levels, consumption rates, shipment volumes, and demand frequency across suppliers and customers. This helps identify consolidation opportunities and optimal replenishment cycles forming the foundation for efficient route design and scheduling Milk Runs.

Determine the number of suppliers to be covered in each milk run cycle based on distances between each supplier and duration. Focus is to minimise transportation lead time, optimum truck utilisation and high frequency replenishment for optimum inventory levels.

Assign dedicated vehicles (preferably side-loading trucks) and decide between in-house or third-party logistics providers for route execution.

Define standardized operating procedures for loading, unloading, scanning, Kanban handling, and issue reporting; train drivers and staff on compliance.

Implement a pilot loop, monitor KPIs like cost, lead time, and inventory reduction; refine the process before full-scale rollout across the network

Milk Run has transformed the way lean organizations manage their supply chains—reducing waste, improving flow, and making replenishment more reliable than ever.

Frequent replenishment lowers safety stock and WIP inventory leading to lower average inventory levels and more efficient use of warehouse space.

Consolidates multiple supplier pickups into a single trip reducing empty truck runs and significantly lowers overall transportation.

Predictable delivery lead times and better inventory tracking and supplier performance monitoring improves supply chain efficiency.

Supplier manufacturer integration with barcode scanning, quick quality checks, and Kanban signal delivery during milk run pickup enhances efficiency and accuracy.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!