By applying Lean Kaizen and cellular manufacturing, the metal tin can manufacturer transformed a high-WIP, long lead-time value stream into a compact, flow-focused operation.

Context and Challenges

A leading metal tin can manufacturer supplying cans to FMCG and industrial customers was struggling with very long throughput time across the supply chain , high WIP inventory and low manpower productivity across its can-making line and unstructured material flow.

The manufacturer was looking to significantly reduce lead time and WIP, improve productivity and create a smoother, more predictable flow using Lean Kaizen – without adding new machines.

Our Approach

As part of a comprehensive improvement program, we followed a four-step process:

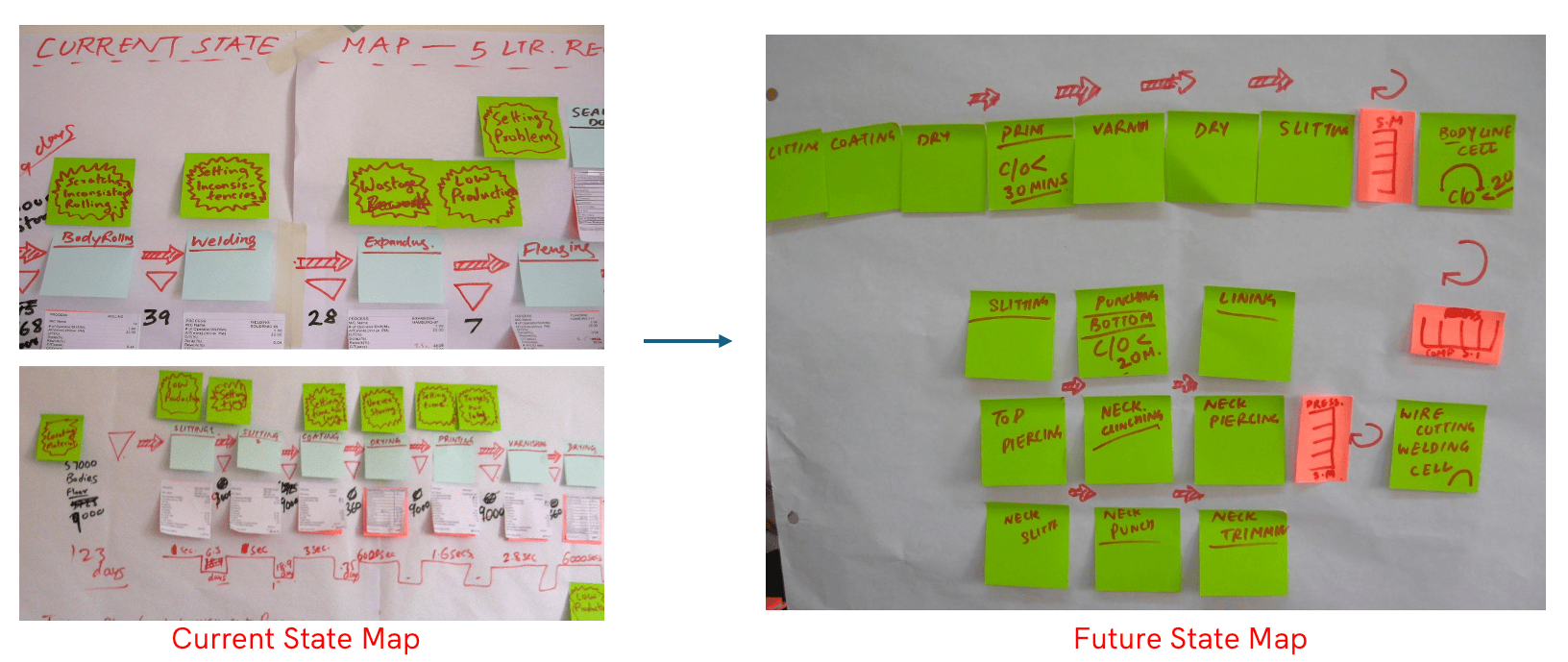

Assessment & Value Stream Mapping: Mapped the current-state value stream from raw material receipt to finished cans, capturing process times, changeover times, WIP levels and waiting times and established baseline KPIs for improvement.

Future-State Design: Designed a future-state value stream with a cellular layout that links key processes into a compact, logical flow (Canline cell).

Kaizen Workshops: Conducted Rapid Improvement Workshops of 5 days each with a cross-functional team to convert the future-state design into practical layout and method changes using lean tools like VSM, Cellular manufacturing, cycle time study and line balancing.

Implementation & Standardisation: Rearranged machines and workstations into a Kaizen Workshops for the selected can line, reducing travel distances and hand-offs. Implemented WIP/kanban limits and simple pull systems to control inventory and standardised work methods.

Key Strategies Implemented

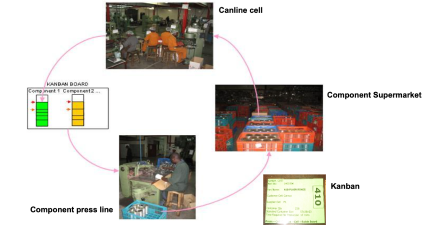

Cellular Layout and Flow Improvement: Converted a traditional  functional layout into a cellular flow for the can line, bringing related processes closer together. Reduced back-tracking and cross-traffic by redefining material pathways and aligning machines in process sequence.

functional layout into a cellular flow for the can line, bringing related processes closer together. Reduced back-tracking and cross-traffic by redefining material pathways and aligning machines in process sequence.

WIP Optimisation and Pull System: Set explicit WIP limits  between key stages by establishing Supermarkets based on Pull systems replacing large batches with smaller, more frequent transfers. Introduced simple pull signals so upstream processes produce in line with downstream consumption, avoiding over-production.

between key stages by establishing Supermarkets based on Pull systems replacing large batches with smaller, more frequent transfers. Introduced simple pull signals so upstream processes produce in line with downstream consumption, avoiding over-production.

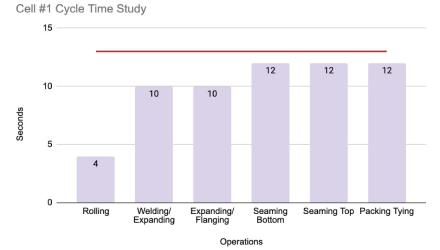

Manpower Productivity and Line Balancing: Performed detailed cycle  time and work-content studies to understand manual effort at each station. Balanced workloads across operators to match TAKT time and eliminated non-value-added walking, waiting and re-handling.

time and work-content studies to understand manual effort at each station. Balanced workloads across operators to match TAKT time and eliminated non-value-added walking, waiting and re-handling.

Standard Work and Daily Work Management: Defined  standard work for operators and daily work management in the new cell, including job sequences, quality checks and housekeeping tasks.

standard work for operators and daily work management in the new cell, including job sequences, quality checks and housekeeping tasks.

Results Achieved

- Throughput time reduced by 76% by redesigning flow, cutting queues and right-sizing batches.

- 42% reduction in manpower used while maintaining and then increasing overall output.

- Manpower productivity improved by 170%, with significantly higher output per person per day due to better line balancing, reduced movement and clearer roles.

- WIP inventory reduced by 99% freeing up floor space and exposing issues early instead of hiding them under piles of stock.

Flow redesign using cellular manufacturing, WIP optimisation and work load balancing content through Lean Kaizen has helped metal tin can plant to significantly reduce lead time, free up space and improve productivity without major capex.