By combining TPM - Autonomous Maintenance, Root cause analysis and SMED within a structured PDCA framework, Paper Bags manufacturing firm transformed long, inconsistent print-to-print changeovers into a disciplined, fast and repeatable process.

Context and Challenges

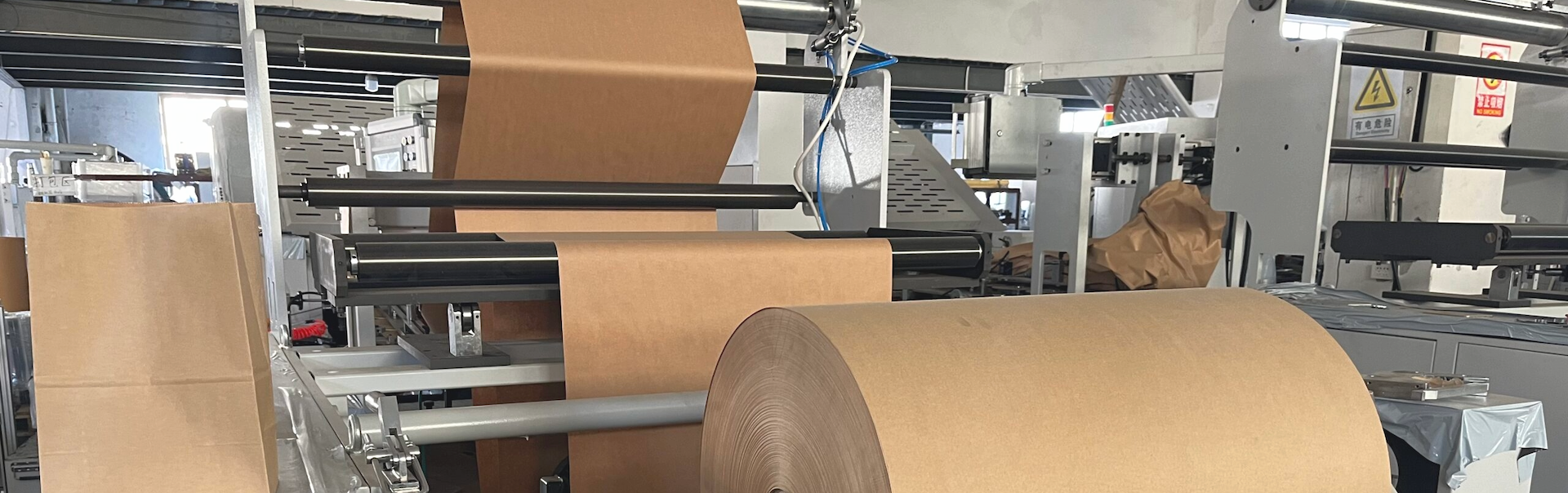

A paper bag manufacturing firm running high-speed printing and bag-making machines for FMCG and retail customers was struggling with very long print-to-print changeovers, frequent minor stoppages and recurring quality issues. Autonomous Maintenance routines were not standardised, and changeover preparation was largely unstructured. Management set a clear objective to improve OEE, sharply reduce changeover time and stabilise machine conditions across the targeted lines.

Our Approach

The improvement was run as a focused PDCA / Jishuken programme on selected print machines and godowns, combining Autonomous Maintenance and SMED.

- Autonomous Maintenance (AM Step 1 – Initial Cleaning): We provided training on basic TPM concepts and carried out deep cleaning on two target machines, exposing hidden defects and abnormal conditions, which were tagged and prioritised for action. Simple daily checklists and an Equipment Control Ledger were used to track routine checks and follow-ups systematically.

- SMED on Print-to-Print Changeovers: We selected high-impact print machines and recorded all changeover steps using detailed time studies and video observation. Activities were classified into internal vs. external and implemented improvements in external preparations.

- Standardisation & Daily Work Management: Developed standard changeover sequences with significantly fewer steps and clearer roles and introduced visual standards for roller settings, plate mounting and cleaning points.

Key Strategies Implemented

- Autonomous Maintenance & 5S on Print Machines: Deep cleaning of critical zones to restore basic conditions, Red / green tagging of abnormalities and systematic closure of issues, creation of daily and periodic checklists for operators and maintenance to prevent forced deterioration.

- SMED & Changeover Time Reduction: Detailed mapping of changeover activities, then elimination, combination or externalisation wherever possible. Clear separation of internal and external tasks and preparation of changeover kits before downtime.

- Visual Management & Standard Work: Simple visual controls at the machine and standard work for operators during changeover: who does what, in which sequence, and within what target time, use of PDCA boards to track actions, before-after photos and improvement status.

Results Achieved

- Print-to-print changeover time reduced by 50%

- Over 40% reduction in changeover steps, , making the process faster, safer and easier to follow

- Time on internal activities cut by 66%

- Improved machine condition and fewer abnormalities