By combining PM Analysis with structured root-cause elimination and daily monitoring, a leading toothpaste manufacturer significantly reduced both underfilled and overfilled material losses on critical SKUs – unlocking recurring savings in PM cost while strengthening process capability.

Context and Challenges

A leading toothpaste manufacturer with multiple high-speed tube-filling lines has been facing persistent overfilling of material issues, resulting in substantial financial losses. Despite earlier improvement efforts and applying various tools and techniques, including root cause analysis, the problem has shown no significant improvement.

There is a need for a structured, engineering-based method to attack PM losses at the source – beyond generic settings and ad-hoc adjustments.

Our Approach

As part of a focused loss-reduction programme, we applied Phenomenon Mechanism (PM) Analysis on the tube-filling process using a four-step approach:

Phenomenon & Line Selection: Analysed PM loss data by formula, size and line to identify where losses were concentrated. Selected lines for overfill and underfill loss reduction with clear goals and targets to achieve.

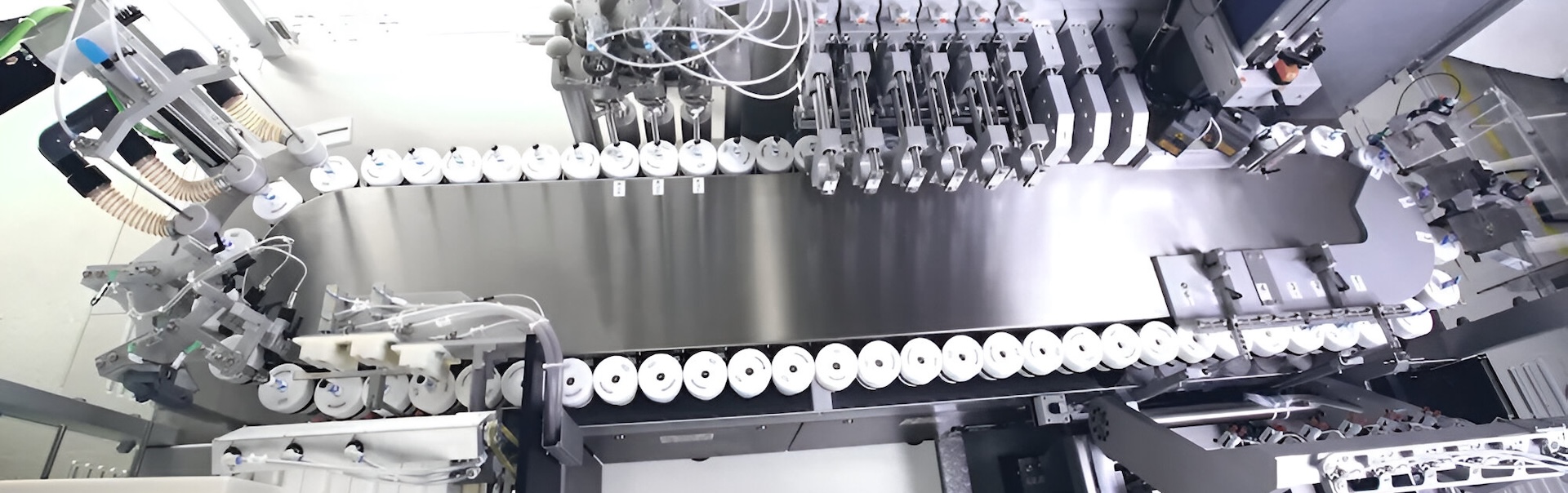

Physical Analysis of Filling Mechanism: Draw a filling mechanism diagram covering Dosing piston, Rotary valve, Shut-off nozzle, Tube lifter, Cream feed pump & pipes, Hopper and connecting pipes from storage tank. Linked the overall phenomenon “weight variation → overfill / underfill” to dosing volume variation at each element of this mechanism.Condition & Mechanism Analysis (PM Analysis): For each subsystem, listed primary and secondary conditions and checked them on the actual machine and identified key abnormalities and initiated focussed root cause analysis to eliminate these.

Root Cause Elimination, Standardisation & Monitoring: Addressed mechanical issues such as seal leaks, worn bushings, loose locking nuts etc, standardised critical settings, created checklists for condition checks at defined frequencies and did routine monitoring of weight distribution, Cpk and % loss at SKU and line level.

Key Strategies Implemented

- Data-driven SKU & line focus using PM loss data to select specific lines where improvement would have the highest financial impact.

- Mechanism-level analysis instead of “trial and error” breaking the filling system into subsystems and conditions so that each abnormality was identified and verified on the shopfloor.

- Structured RCA and Kaizen execution to address 8 high-impact abnormalities through targeted replacement, reconditioning and re-setting actions, rather than general overhauls.

- Standard work and checklists for maintenance & operations to ensure critical clearances, tightening, lubrication and component conditions are sustained, not just fixed once.

- Ongoing performance monitoring integrating % loss, Cpk and weight spread for focus SKUs into routine review, with actions logged and tracked until closure.

Results Achieved

- 30% Overfilled loss reduction improving material yield

- 25% CpK improvement,

- 30%+ reduction in variation

- Improved equipment condition and stability

- Stronger process capability and visibility

Overall, the PM Analysis project turned a chronic, data-visible but poorly understood PM loss into a controlled, mechanism-level improvement, delivering recurring savings and a robust method that can be replicated on other filling lines and formats.