Automotive manufacturers today operate in an environment of volatile demand, variant proliferation, and intense cost pressure. OEMs, passenger and commercial vehicle manufacturers, component suppliers, and battery plants must deliver high quality at low cost, with reliable delivery and shorter lead times.

Common challenges include:

Lean Kaizen helps automotive plants systematically eliminate waste, stabilize processes, and build reliable, flow-based operations—from machining and casting to final assembly

Lean Manufacturing System for Automobile operations combines VSM, line & layout design, standard work, SMED, TPM, and TQM to drive improvement across assembly, machine shops, suppliers, and logistics.

On vehicle assembly lines, Lean Kaizen focuses on balancing work content, eliminating operator movement, and designing flow-based layouts by

This helps achieve higher throughput per day, reduced operator fatigue, and consistent performance across shifts.

Equipment Reliability & Breakdown Reduction (Machining, Casting, Assembly)

Machine shops and casting areas often drive availability losses in automotive value streams. Lean Kaizen applies TPM and detailed breakdown analysis to improve reliability:

This approach is used to reduce equipment failure losses, adjustment losses, and speed losses, directly improving OEE and conversion cost.

Quality & Defect Reduction in Machine Shops & Assembly using TQM, Lean & Six sigma approach can drastically reduce rejections by using below approach:

Automotive plants often suffer from low OEE and increasing conversion costs, especially where manual intervention is high. Lean Kaizen improves both equipment utilization and manpower productivity:

Automotive manufacturers lose significant productivity in internal logistics and line inventory. Lean Kaizen improves flow by:

This results in shorter throughput time, improved space utilization, and lower inventory carrying costs from machine shop to final assembly.

People capability is central to automotive Lean transformations. Your case studies highlight Training Within Industry (TWI) and Jishuken as key levers:

This allows plants to increase operator efficiency, demonstrating that “more work can be done with fewer people” when MUDA is eliminated and lines are balanced.

Sustainable improvement in automotive requires basic stability:

These practices make abnormalities visible and enable quick action, supporting zero-defect and zero-breakdown goals.

Increase in vehicle output per day

Improvement in manpower productivity

Reduction in breakdown hours

Reduction in rejection and rework

Reduction in conversion cost per unit

We help tractor and vehicle manufacturers achieve high line productivity and consistent quality through flow manufacturing, line balancing, and standardized work. By redesigning layouts, eliminating non-value-adding movements, and stabilizing processes with TPM, plants increase throughput, reduce fatigue, and lower cost per vehicle.

We improve OEE, yield, and manpower productivity by eliminating chronic losses across assembly, heat-sealing, testing, and formation. Through TPM tools and SMED, we enhance equipment reliability, accelerate changeovers, and significantly reduce rejection, rework, and conversion cost per unit.

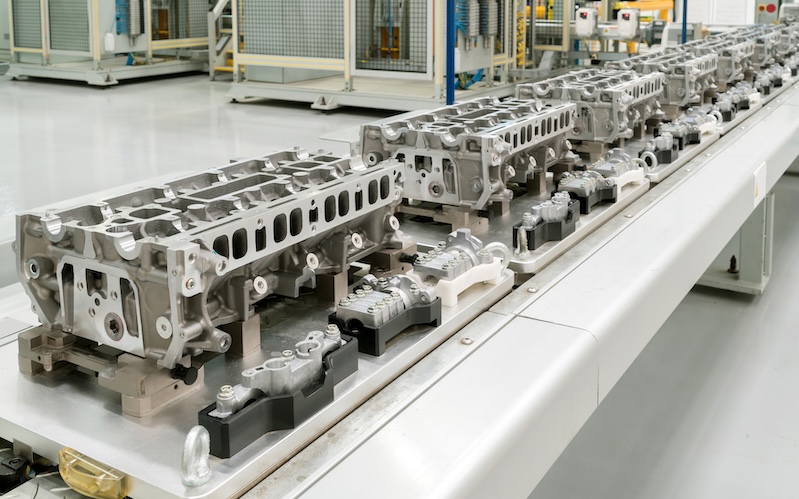

Component and machining suppliers benefit from Lean Kaizen through defect prevention, process stability, and faster delivery. Using TPM, QC Story, and flow manufacturing, we help teams reduce breakdowns, rejections, and rework while improving tool life and cycle time. resulting in higher reliability and lower cost.

In an automotive landscape defined by volatile demand, rising costs, and increasing product complexity, Lean Kaizen enables manufacturers to stabilize processes, eliminate waste, and build reliable, flow-based operations —from machining and casting to final assembly.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!