Kaizen, meaning ‘continuous improvement’ in Japanese, is a philosophy and a practical methodology for achieving sustainable efficiency, quality, and productivity improvements. Through small, incremental changes driven by employees at all levels, organizations create long-lasting cultural transformation.

The focus of Lean Kaizen is to continuously reduce Business Throughput time by identifying, reducing and eliminating MUDA (Waste). The core idea is to maximize customer value while minimizing waste. We help organisations integrate Kaizen into their culture with extensive Kaizen training programs.

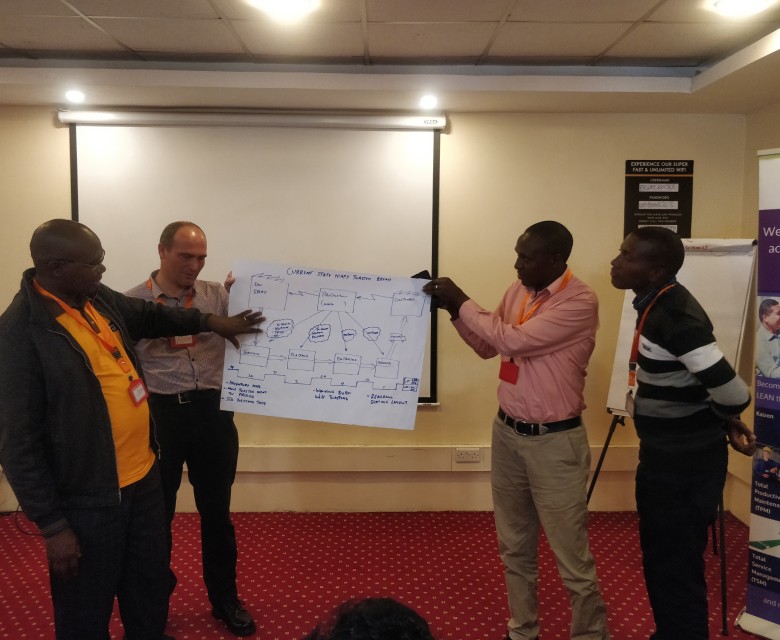

Our Kaizen Facilitator training programs empower managers to apply Lean Kaizen tools effectively, fostering operational excellence and continuous improvement across the organization. We transform managers into Kaizen Leaders through practical, experience-driven learning that blends interactive presentations, real-world case studies, experiential simulations and games, collaborative group work, and hands-on practice at the Gemba.

Our team has conducted over 5000 Kaizen workshops across 80+ different industries & Trainings on, 5S, Lean Manufacturing, Just-In-Time, Total Productive Maintenance (TPM), Total Quality Management, Total Flow Management (TFM), Daily Work Management, Preventive Maintenance, Internal Kaizen Expertise and Hoshin Kanri.

Kaizen Leader Certification Training is a 4-day training program designed to provide participants with skills and knowledge to identify and analyse problems, implement and review kaizen projects successfully through internal Kaizen workshops to facilitate daily improvements.

Building Right Mindset for Kaizen

Kaizen Fundamentals

Waste Identification with Value Stream Mapping

Flow Management and Standard Work

Creating Pull Systems

Root Cause Analysis

TPM Overview

TPM Pillar Deep Dive

Kaizen Project Facilitation

Autonomous & Planned Maintenance – Advanced Steps

Human Skill Development for Kaizen Leaders

Quality and Process Improvement Tools

Kaizen trainings conducted

successful Kaizen projects

participants trained

Sharing of experience and case studies with practical application by Kaizen experts, worked across various industries and sectors.

The training program is tailored to align with organisation goals, by initial discussions with key stakeholders.

Practical learning through group activities, case studies, and simulation games, ensuring an engaging and hands-on experience at both classroom and shop floor of implementing Kaizen.

Train-the-Trainer program is led by a highly experienced trainer and Lean Kaizen expert to enable internal capacity building and empower teams for ongoing success.

Flexible online and off-site Kaizen training programs designed to suit the needs of the organisation.

Participants will get certification only after the submission of defined Kaizen projects and results delivered, ensuring target outcomes are achieved for each project.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!