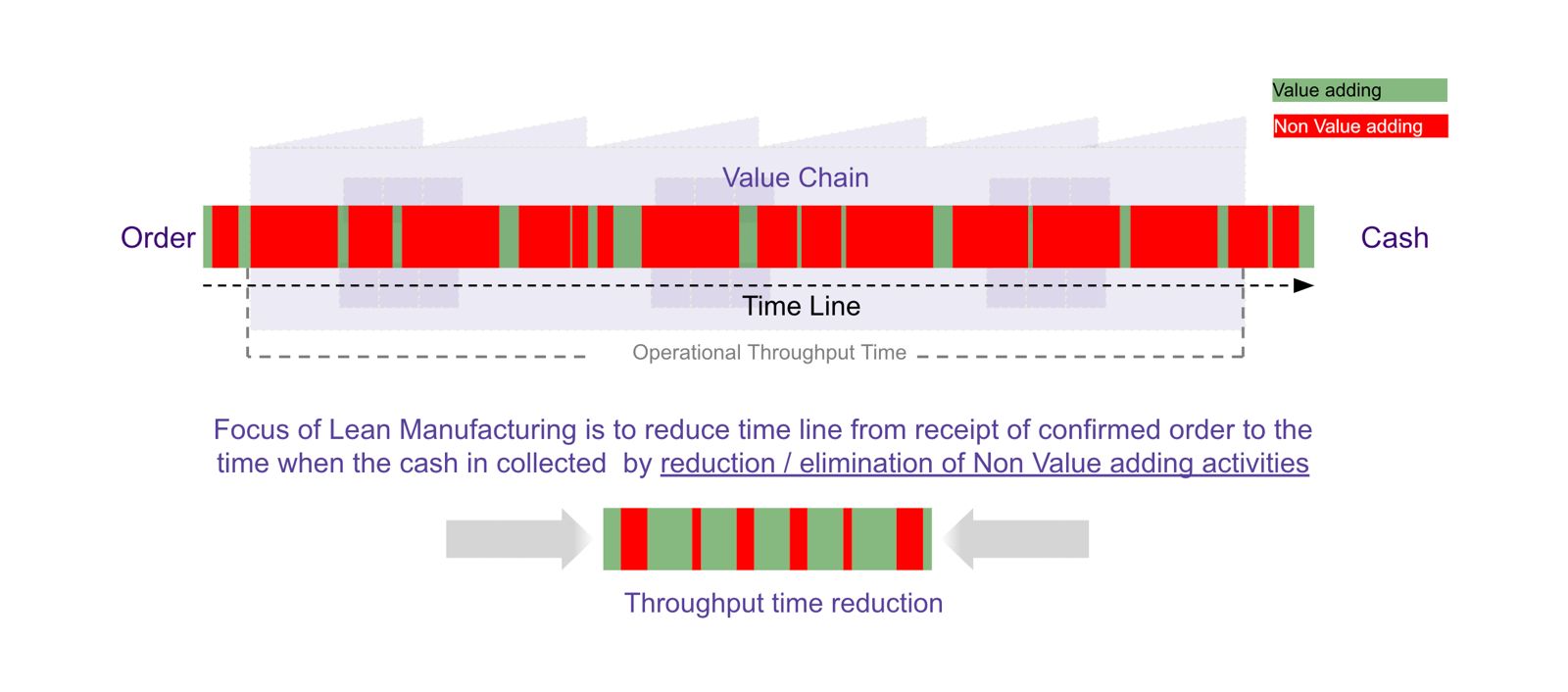

Reducing lead time is a critical factor in modern manufacturing, driven by growing demand for faster delivery, mass customization, and leaner operations. Lead time reduction involves streamlining processes to minimize the duration from the initiation of an activity—such as order receipt or production start—to the final delivery of the product

As supply chains become more dynamic, lead time reduction is no longer optional—it’s a strategic advantage. We help you maximize utilization of resources through elimination of waste & losses and reduce business throughput time by leveraging proven strategies of Lean Kaizen. By streamlining workflows, eliminating bottlenecks, and minimizing delays, companies not only improves responsiveness to market changes but also boosts overall efficiency, reduces inventory holding costs, and strengthens profitability.

“Reducing lead time means producing more in less time—unlocking greater output, efficiency, and customer satisfaction.”

Reduction in overall lead time

Increase in on-time delivery

Improvement in manpower productivity

Decrease in WIP inventory

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!