Master Lean Six Sigma with our comprehensive Lean Six Sigma training programs designed to drive operational excellence, reduce waste, and enhance quality. This training helps you learn the powerful approach of integrating Six Sigma tools and techniques and Lean methodologies to improve speed, reduce variations and defects for higher efficiency.

Lean Kaizen is “doing more with less”.

Six Sigma is the use of rigorous statistical analysis tools to uncover persistent quality problems.

Lean Six Sigma, a blending of the two approaches that eliminates the guesswork about when and how to use the tools and compresses the time it takes to implement and realize gains.

By combining the principles of Lean with the statistical rigor of Six Sigma, it forms a strategic framework for driving continuous improvement.

Our Lean Six Sigma Yellow Belt training program is an introductory level program designed to provide a basic understanding of Lean Six Sigma principles and methodologies to help individuals support improvement initiatives, participate in problem-solving teams, and apply Lean Six Sigma principles in their day-to-day work.

Lean Six Sigma Yellow Belt Training Topics

Preparing Right Mindset for Lean

Key Principles of Lean: Understanding of Value adding, Non-Value adding activities, 8 Wastes

PDCA Methodology: 5S & Visual Management

Flow Manufacturing: Principles of flow manufacturing, TAKT Time, line balancing

Key Lean TPM tools: Understanding OEE & Losses and Autonomous Maintenance Step 1

Six Sigma Basics, DMAIC process

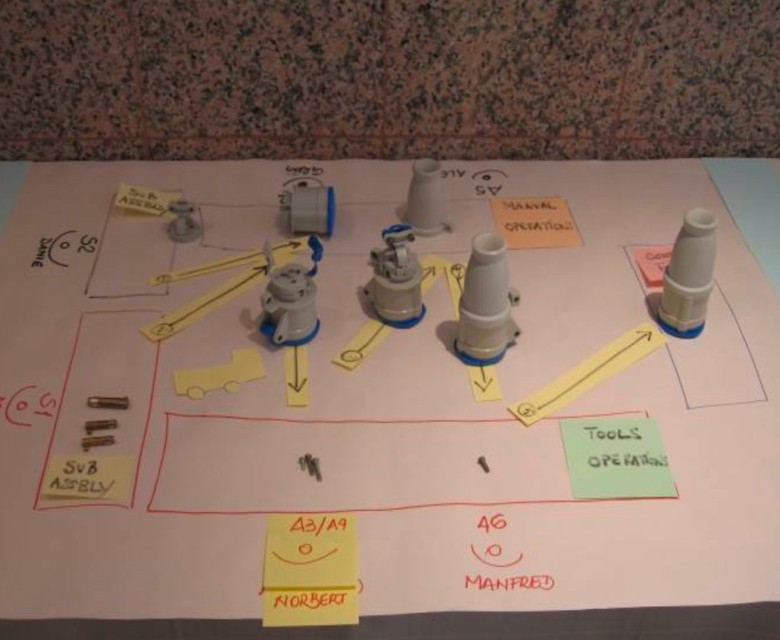

Case studies and Simulation games

Lean Six Sigma Green Belt Training is a comprehensive program designed to equip professionals with the knowledge and skills necessary to lead and support medium sized process improvement projects, support larger projects and use lean six sigma tools and identify improvement opportunities within the organization.

Lean Six Sigma Green Belt Training Topics

Building Lean mindset, Paradigm shift

Key Principles of Lean: Understanding of Value adding, Non-Value adding activities, 8 Wastes

Value Stream Mapping for Waste Identification: Learn to create current state map

Flow Manufacturing: Principles of flow manufacturing, Cellular / Flow manufacturing based on Cycle time, TAKT Time, Line balancing

Key TPM tools: Understanding Chronic & Sporadic Losses, OEE Losses Measurement and Autonomous Maintenance Step 1-2

Six Sigma Basics, DMAIC, Problem solving methodology

Case studies and Simulation games

Lean Six Sigma Black Belt Training is an advanced, intensive program designed to create experts in Lean six sigma principles and tools to lead large scale process improvement projects, drive organizational change, and deliver substantial business results. Black Belt training equip individuals to conduct deeper analysis using Lean Six sigma tools, and contribute to strategic thinking and data-driven decision making.

Lean Six Sigma Black Belt Training Topics

Overview of Green Belt: Key Lean Principles & tools

Lean tools : Black Belt

Six Sigma, DMAIC, Problem solving methodology

Define: Project charter, Cost of Poor Quality

Measure Phase:

Analysis Phase

Improve Phase: Mistake Proofing

Control Phase: FMEA

Case studies and Simulation games

Lean Six Sigma trainings conducted

successful Lean Six Sigma projects

participants trained

Sharing of experience and case studies with practical application of Lean Six Sigma by Lean experts, worked across various industries and sectors.

The training program is tailored to align with organisation goals, by initial discussions with key stakeholders to identify major challenges and select relevant six sigma tools.

Practical learning through group activities, case studies, and simulation games, ensuring an engaging and hands-on experience at both classroom and shop floor of implementing Lean Six Sigma.

Train-the-Trainer program is led by a highly experienced trainer and Lean expert to enable internal capacity building and empower teams for ongoing success.

Flexible online and off-site Lean Six Sigma training programs designed to suit the needs of the organisation.

Participants will get certification only after the submission of defined Lean Six Sigma projects and results delivered, ensuring target outcomes are achieved for each project.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!