The Japanese term MUDA translates to “waste”. In any manufacturing process, at each stage of transforming raw material into final product or service, value should be added—whether through physical transformation, information processing, or service delivery.

However, not all activities contribute to this value creation. Muda refers to any activity that consumes resources but does not add value from the perspective of the customer. These non-value-adding activities hinder productivity, increase costs, and reduce overall efficiency.

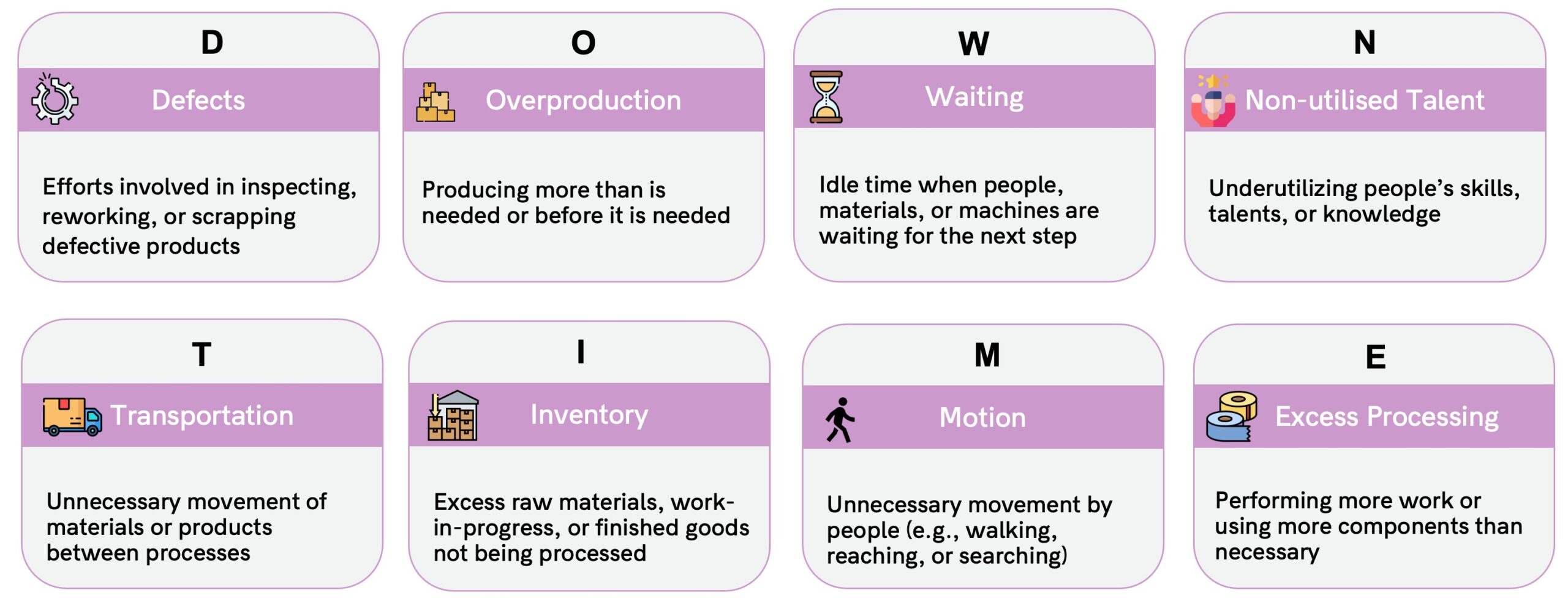

To systematically identify and eliminate waste, muda is categorized into eight types, which can be conveniently remembered using the acronym DOWNTIME.

Eliminating Muda through Kaizen is not just a tool but a strategic necessity in modern manufacturing. By identifying and minimizing these eight types of waste, organizations can streamline their processes, improve quality, reduce costs, and enhance customer satisfaction. As industries evolve, companies that continuously identify and reduce waste—both physical and digital—gain a significant edge in efficiency, sustainability, and innovation.

D-Defects

Defects disrupt production, require costly rework, and often result in scrapped materials—wasting time, resources, and effort. In traditional mass production, high-speed machines can generate large volumes of defective products before issues are detected, potentially damaging tools or equipment.

Defects are caused by various issues at gemba such as machine problems, issues with material quality, operator skills and work methods used.

Muda of defects can be addressed using tools such as Root cause analysis, 7QC tools, Statistical process control and Six sigma.

O-Overproduction

Overproduction, called the Mother of all other types of muda (waste), occurs when more is produced than needed—often driven by fear of machine failures, defects, or absenteeism. While it may appear efficient, it leads to excessive use of materials, labor, space, and costs, masking real problems and disrupting production flow.

In Lean manufacturing, being ahead of schedule is worse than being behind. Overproduction creates a false sense of productivity and hinders continuous improvement (kaizen). It stems from misaligned incentives like maximizing machine use rather than meeting actual demand.

Muda of overproduction can be addressed using tools such as Kanban and pull system.

W-Waiting

Muda of waiting occurs when operators are idle due to line imbalances, part shortages, or machine downtime. It also includes time spent monitoring machines during automated processes. Even when operators appear busy, valuable time may be lost simply watching machines, contributing no added value.

Eliminating this waste requires better synchronization and continuous flow techniques such as line balancing, cellular manufacturing, total productive maintenance and 7 QC tools.

N-Non Utilized Talent

Muda of Non Utilised talent refers to the underuse of employees’ skills, knowledge, and creativity. It occurs when workers are not empowered to contribute ideas or are assigned tasks below their capability.

This leads to disengagement, lower productivity, and missed improvement opportunities. Fully utilizing people’s potential is essential for continuous improvement and innovation.

Involvement of employees in kaizen projects with CI bases reward and recognition helps boost motivation and create a culture of continuous improvement.

T-Transport

Transport muda refers to the unnecessary movement of materials, which adds no value and often increases the risk of damage. While transport is necessary, excessive reliance on tools like forklifts and conveyor belts signals inefficiency—especially when processes are physically isolated.

Integrating these “islands” into the main flow can reduce waste. Transport, along with excess inventory and waiting, is one of the most visible forms of waste on the shop floor (gemba).

Kaizen practices, such as 5S and optimizing workflows, can significantly improve operations.

I-Inventory

Inventory—whether final products, semi-finished goods, or parts—adds no value and only increases operational costs by consuming space, requiring equipment, and demanding additional personnel.

Excess inventory deteriorates over time, risks damage, and conceals underlying issues like defects, downtime, or inefficiencies. It is often the result of overproduction/ High inventory levels give a false sense of security, while lower levels expose problems and drive continuous improvement (kaizen).

Kaizen tools such as 5S, kanban and pull system can significantly reduce high inventory wastes.

M-Motion

Any human motion that does not directly contribute to value creation is considered waste (muda). Movements such as walking, reaching, or lifting heavy objects add no value and should be minimized or eliminated—both to improve efficiency and reduce physical strain on workers.

Often, simple workplace redesigns can eliminate unnecessary motion. Observation shows that actual value-adding actions take only seconds, while the majority of time is spent on non-value-adding tasks like handling, repositioning, or transferring parts. Streamlining motion is essential for improving productivity and supporting lean practices.

Standard work, 5S, flow layout are some of the key lean tools that are used to reduce non-value adding movements and improve manpower productivity.

E-Extra Processing

Muda of extra processing arises when technology, design, or workflow inefficiencies cause unnecessary effort during value-adding tasks. Examples include excessive machine overruns, redundant press actions, or post-processing steps like deburring.

Often, such waste can be eliminated through common-sense, low-cost solutions, such as combining operations or redesigning process flow. Processing waste also results from poor synchronization and overprocessing—doing more than what is required—which adds cost without adding value.

Muda of extra processing can be addressed using tools such as poke yoke, jigs, standard work.

MUDA projects implemented

Reduction in MUDA

People trained on MUDA reduction

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!