A value stream in manufacturing includes all activities (value-creating and non-value-creating) that are required to transform raw materials and information into a finished product or service. It encompasses everything from the sourcing of raw materials, through production processes, to the final delivery of goods to customers.

In today’s competitive landscape, the ability to deliver faster, at lower cost, and with higher quality is crucial. Value Stream Mapping is a lean tool that provides a high-level visual of all steps—both value-adding and non-value-adding—in your process flow. It helps you understand where delays, inefficiencies, and bottlenecks exist from the moment raw materials enter your facility to when the finished product reaches your customer.

By creating a visual representation of the entire value stream, manufacturers can make informed decisions, prioritize improvement actions, and implement changes that lead to a more streamlined, waste-free production process.

Identify and eliminate non value adding activities (muda)

Streamline workflows, optimize resource utilization, and reduce process inefficiencies

Reduce equipment downtime and imbalanced workloads

Lower inventory, cost of poor quality and operating costs

Identify inefficiencies in workflows and enhance manpower productivity

Eliminate defects, rework and human errors

Ensure On-time Delivery and quality products to customers

Value Stream Mapping doesn’t just visualize your process—it reveals the hidden costs, inefficiencies, and delays. It’s a blueprint for operational excellence, driving faster delivery, lower costs, and higher customer satisfaction.

Preparation is a crucial foundation for effective Value Stream Mapping (VSM), involving the collection of baseline data, identification of key stakeholders, and clear alignment on the scope and objectives to ensure meaningful and successful implementation.

Key steps involved in preparation phase are:

Training on Value Stream Mapping

We begin by aligning stakeholders through targeted training sessions on Value Stream Mapping principles, ensuring the team understands the methodology, objectives, and expected outcomes. This foundational knowledge empowers team members to actively contribute to the mapping and improvement process.

Selection of Product families

Using a data-driven approach that combines routing analysis and the Pareto principle, we identify product families with the highest production volumes and the greatest potential for ROI. This ensures we prioritize streams that yield the highest impact on operational and financial performance.

Identification of cross functional teams

Cross-functional teams that include members from production, quality, planning, maintenance, and supply chain are formed for VSM. Their collective insight ensures a holistic view of the value stream and facilitates effective identification of constraints and improvement opportunities.

Data collection from gemba

We focus on collecting real time data from gemba for both current and future state mapping. It includes product SKUs, annual sales, plant layout, cycle time, manpower productivity, production capacity, downtime, changeover time, inventory planning & control, rejections, delivery time, sales loss or customer complaints if any.

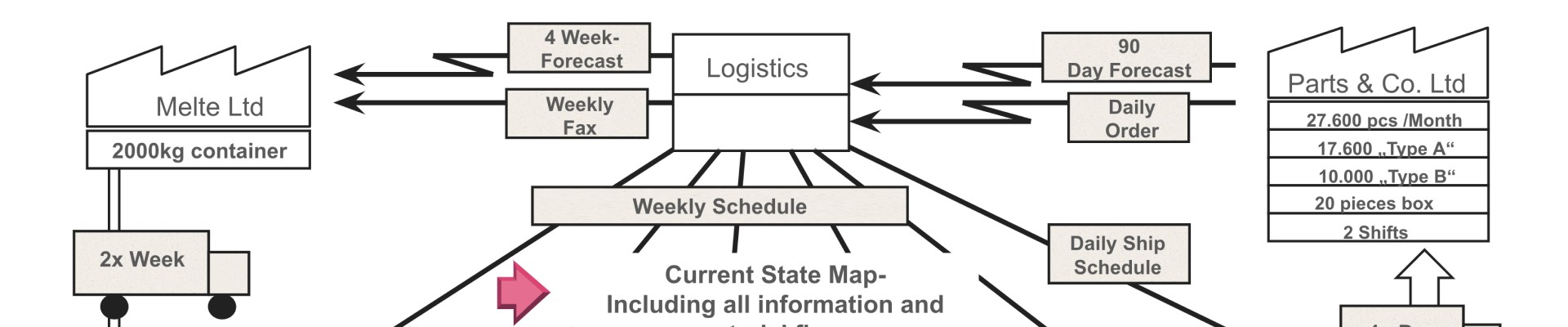

Current state mapping focuses on analysing your existing process flow, capturing key data like cycle times, changeover times, inventory levels, and throughput. Our team walks your floor with your operators to build a true, data-driven picture of your operations and identifies Kaizen bursts & improvement opportunities with your internal teams.

Key steps of creating Current state Value stream map

Map Material Flow

The current state mapping process begins with documenting key customer information, including demand, order frequency, and shipment size. Flow of materials from the customer to raw materials is mapped with key process steps using standard icons or symbols, and use additional rows for parallel processes where necessary.

Capture Process Data & Inventory levels between the processes

Essential data for each process step, such as cycle times, batch sizes, setup times, and processing times is captured and mapped for each process. Inventory levels between each process including storage areas in capture using inverse triangle icons

Map Information Flow

Information flow is mapped focusing on how customer orders are received and how information flows from customer and production planning to production

Identification of Kaizen bursts and calculation of Value adding ratio

After mapping material and information flow, non-value-adding activities are identified and marked as Kaizen bursts, highlighting improvement opportunities. These include delays, rework, overproduction, and other inefficiencies. The Value-Adding Ratio and Lead Time are then calculated to complete and assess the current state map.

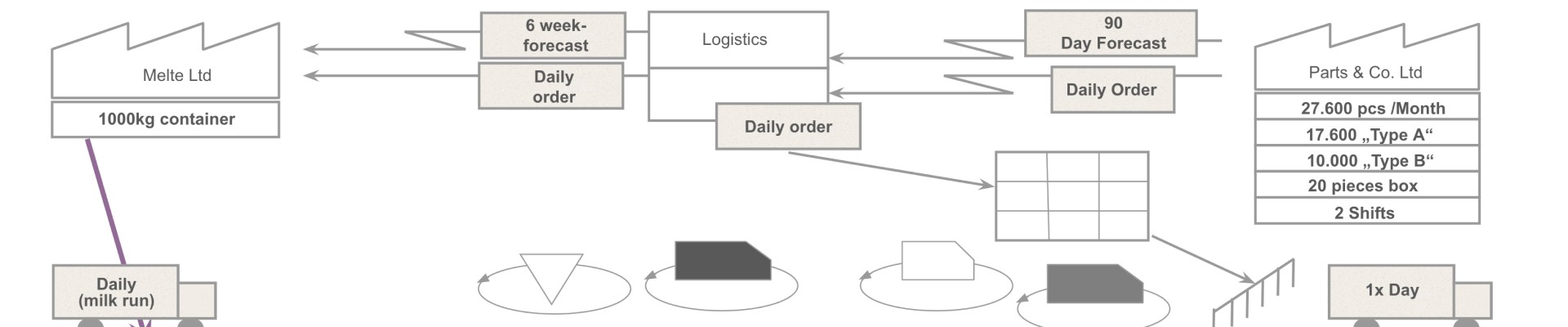

The purpose of creating a future state map is to visualize and design an improved operational state that eliminates waste, reduces lead time, enhances efficiency, and optimizes overall performance. Serving as a blueprint, the future state map guides the transformation of the value stream toward its desired goals.

Key steps of creating Future state Value stream map

Establish Strategic objectives

Clearly defined goals of the future state, such as reducing lead time, eliminating waste, improving flow and layout, reducing defects, and enhancing Overall Equipment Effectiveness (OEE) are established and serve as the foundation for designing a more agile and efficient value stream.

Design improved material and process flow

An improved material and process flow that incorporates lean principles—such as continuous flow through streamlined layouts, downtime reduction via Total Productive Maintenance (TPM), implementation of pull systems for inventory control, and standardized work practices to ensure consistency and efficiency.

Design improved information flow

Improved information flow using lean tools like Kanban, Heijunka (level scheduling), and pull-based systems is designed with focus on reducing non-value-adding communication delays

Set targets and create Kaizen roadmap

Measurable performance targets and a structured Kaizen Roadmap is established to achieve the destined future state map.. This roadmap ensures sustained momentum and accountability in achieving the future state

Value Stream Mapping projects completed

Lead time reduction

Cost reduction

Reduction in inventory levels

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!