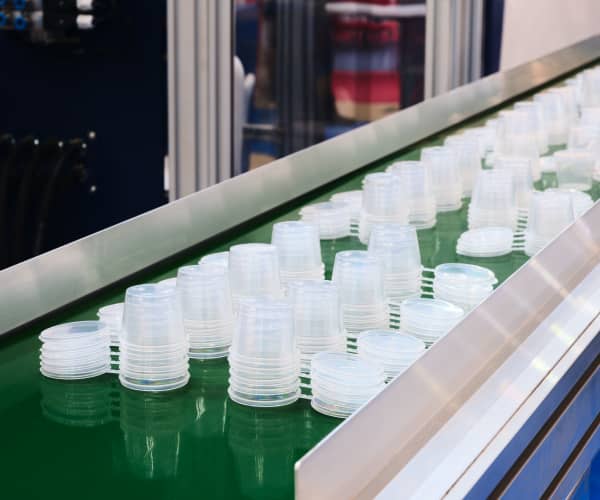

Packaging manufacturers operate under tight margins, fluctuating raw material prices, and demanding customer expectations for print quality, strength, and delivery reliability. Most plants manage a wide mix of products and SKUs—ranging from jute bags for agriculture and cement, to poly bags and liners, flexible laminates for FMCG, disposable cups and containers, and paper bags for retail and food service.

Without structured Lean Kaizen, they usually struggle with:

Lean Kaizen helps packaging plants turn this complexity into a competitive advantage by creating flow-based, low-waste, well-planned operations.

Increase in line output / OEE

Reduction in changeover time

Reduction in material waste and scrap

Improvement in labour productivity

Reduction in customer complaints and internal rework

By stabilising looms through TPM, improving batching and warping flow, and reducing rework in stitching and bale formation, mills can increase tonnes per loom per day while cutting waste and off-quality.

SMED and better process control on extrusion and sealing, and improved scrap segregation reduce both waste and changeover time. Planning improvements and WIP control help maintain on-time delivery for key SKUs with lower overall inventory.

Flow-based layouts, centreline process control and structured problem solving reduce rejections and re-runs. Downstream, pouch-making productivity, cleanliness improve with better 5S, changeover practices and visual management.

Standard settings, faster tool changes and improved scrap control at forming and punching stages deliver more units per shift with less wastage. Well-organised pack-off areas and warehouses help manage volume spikes efficiently.

Optimised cutting and printing layouts reduce trim and misprints, while SMED on size and design changes cuts downtime. Strengthening in-process checks and 5S at machines and in RM/FG stores improves both yield and delivery performance to customers.

Lean Kaizen helps packaging firms turn high-mix, high-pressure operations into stable, low-waste and high-throughput plants by improving OEE, reducing defects, streamlining changeovers and strengthening flow and daily discipline.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!