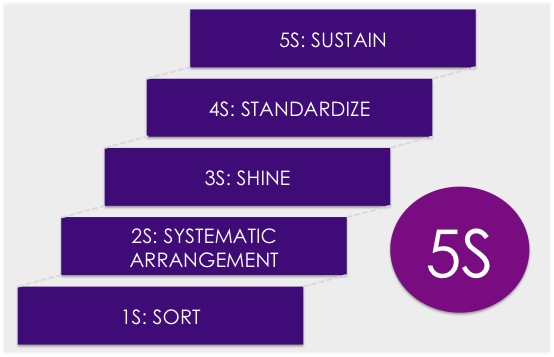

5S

5S is a method to improve and sustain workplace organisation. 5S represents 5 disciplines for maintaining a visual workplace (visual controls and information systems).These are foundational to continual improvement and a manufacturing strategy based on “Lean Manufacturing” (waste removing) concepts.

5S help reduces clutter, reduces the time it takes to look for tools and equipment. Improves how the operation appears to customers – always be “tour ready”. Creates pride in the workplace. Many companies have a standard that any tool must be able to be found within 60 seconds.

One of the Key Principle of 5S is have

“A place for everything and everything in its place”

5S are 5 Japanese / English words starting from the word S

1S – Sort: Remove all unnecessary materials and equipment

2S – Systematic Arrangement: Make it obvious where things belong

3S – Shine: Clean everything, inside and out

4S – Standardise: Establish policies and procedures to ensure 5S

5S – Sustain: Training, daily activities,

Safety (often called “6S” or “5S + 1”)

In East African Language (Kiswahili) – 5S is known as 5K. 5 Kiswahili words starting from the word K.