Continual Improvement – Lean Kaizen

We help you maximize utilization of resources through elimination of waste & losses and Reduce Business throughput time by leveraging proven strategies of Lean Kaizen.

Lean Kaizen is all about doing more with Less..

Lean Kaizen is a way of seeing and managing the way work is done in a manner that allows you to identify and eliminate waste. It is not a concept – a way of thinking, it is not a tool…It’s a philosophy, a culture that MUST be practiced throughout the organization, day in and day out.

In today’s fast paced world, speed and agility of process is a critical factor that enables quick delivery to customers. Lean Kaizen is a business approach based on the fundamental goal of eliminating waste and maximizing flow. A lean organization is one that fully understands, communicates, implements and sustains lean concepts seamlessly throughout all operational and functional areas. The lean process is one in which all employees of the company are involved and obessed about eliminating waste.

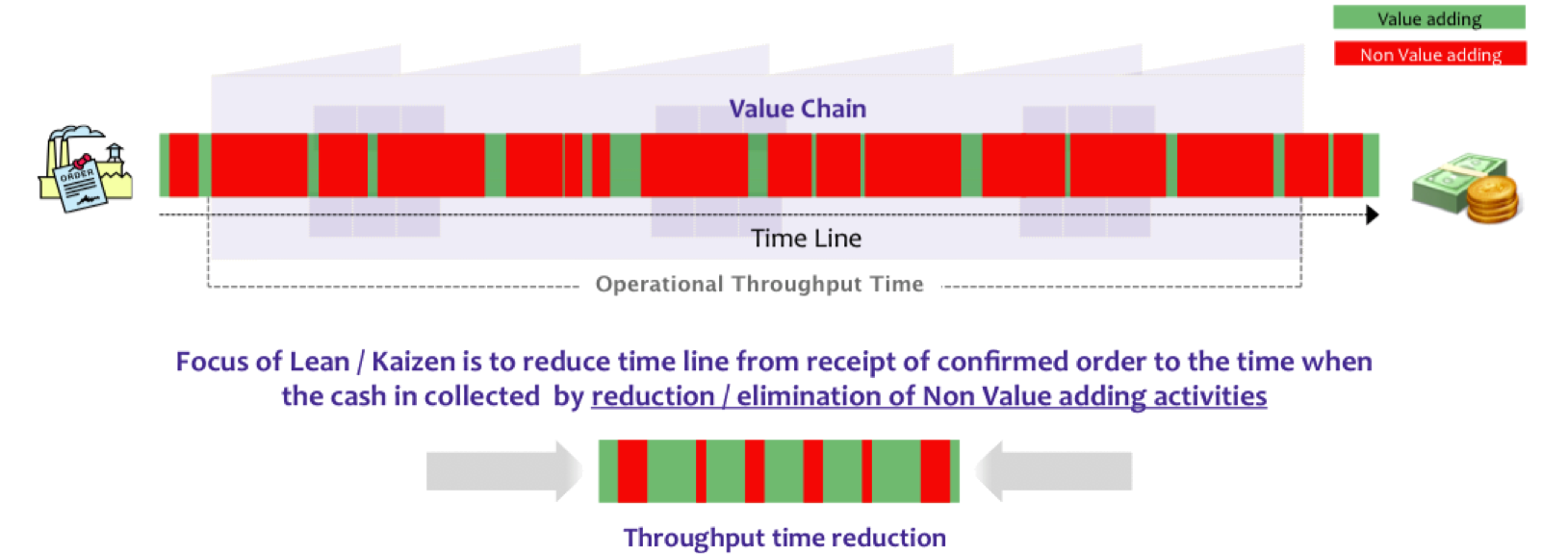

Focus of Lean Kaizen is to continuously reduce Business Throughput time by identify, reducing and eliminating MUDA (Waste) .The core idea is to maximize customer value while minimizing waste. Simply, lean means creating more value for customers with fewer resources. To accomplish this, lean kaizen thinking changes the focus of management from optimizing separate technologies, assets, and vertical departments to optimizing the flow of products and services through entire value streams that flow horizontally across technologies, assets, and departments to customers.

Eliminating waste along entire value streams, instead of at isolated points, creates processes that need less human effort, less space, less capital, and less time to make products and services at far less costs and with much fewer defects, compared with traditional business systems. Companies are able to respond to changing customer desires with high variety, high quality, low cost, and with very fast throughput times. Also, information management becomes much simpler and more accurate

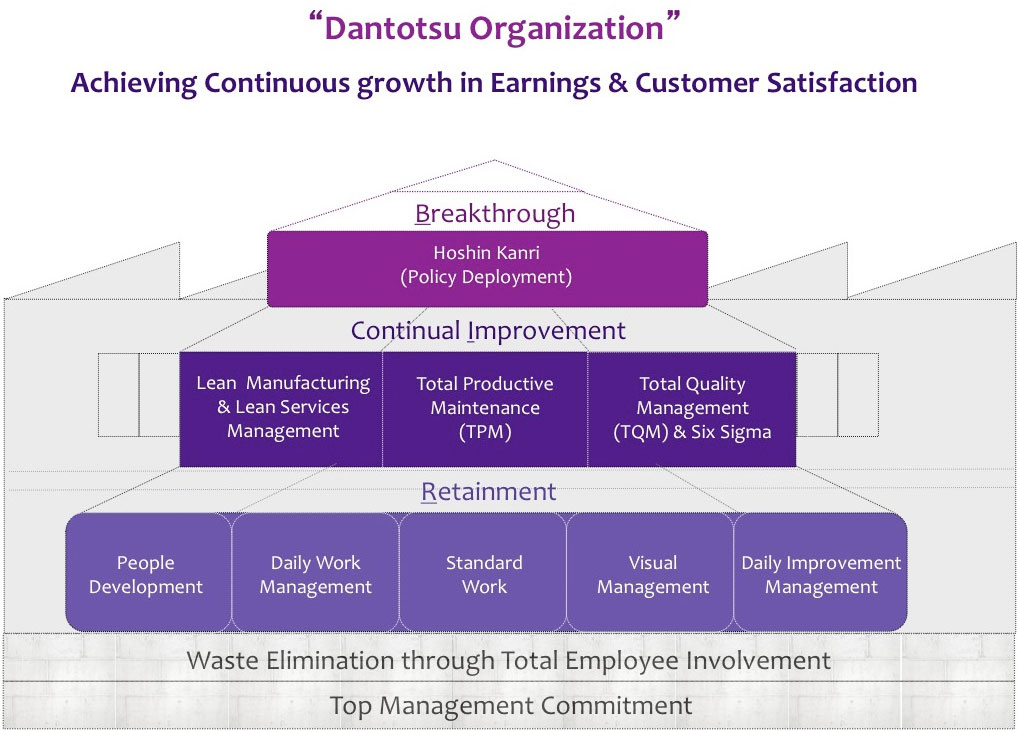

We help our client companies to Implement Lean Kaizen in a systematic manner and focusing on the entire value stream for process optimization through waste elimination. Our Consulting services can help you in implementing various tools in Lean manufacturing through our RIB Model.

Our Unique RIB Model focuses on 3 Main Tools of Improvement: Lean Management, Total Productive Maintenance & Total Quality Management.