Overall Equipment Effectiveness (OEE) is the global standard for measuring equipment capacity utilization. By assessing three core aspects—Availability, Performance, and Quality—OEE helps to know how well a manufacturing process is performing relative to its full potential.

Organizations prioritising equipment performance are assured that their assets are being utilized efficiently, driving maximum output while minimizing costs. By leveraging Overall Equipment Effectiveness (OEE), companies can optimize equipment performance, leading to increased productivity, cost reductions, and enhanced competitiveness. Maximizing OEE ensures that every asset operates at its full potential, contributing to a more streamlined and profitable operation.

We specialize in helping manufacturing companies improve Overall Equipment Effectiveness (OEE), a key metric that drives productivity, reduces costs, and enhances quality. With our proven strategies and deep industry expertise, we help you unlock the full potential of your operations.

Clients

Industries

OEE Successful Projects

ROI

Assessment by our OEE experts at shop floor to gather data on your equipment’s availability, performance, and quality to evaluate current OEE performance, identify key losses and its causes and benchmark current OEE against industry standards to estimate improvement targets and financial benefits.

Customised training on OEE concepts and improvement strategies, through classroom and shopfloor training, to identify and address key equipment issues quickly. We ensure that your team develops the right mindset to maximise OEE.

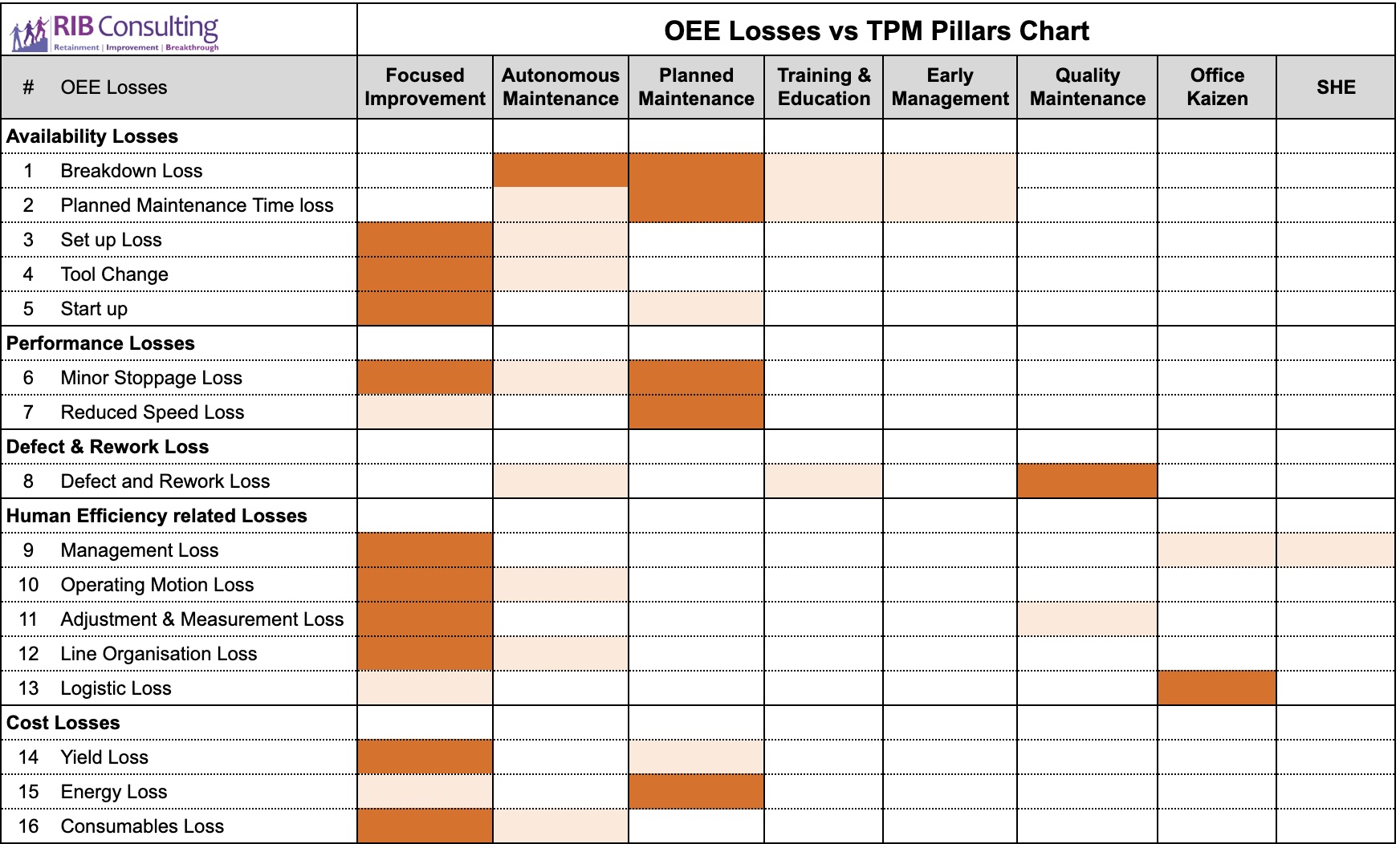

We help you minimise OEE losses through implementation of Total Productive Maintenance (TPM) pillars. Prioritization of improvement efforts is done by addressing the most significant losses first such as breakdowns, changeover times, Speed losses and defects

Our experts will assist in establishing a robust OEE management system to maximise, monitor and sustain OEE. This framework is designed to track OEE on a continuous basis, review losses, achieve desired results and sustain improvement.

Reduction in breakdowns

Reduction in changeover time

Reduction in speed loss and minor stoppages

Reduction in defects and rejection

Total Productive Maintenance (TPM) plays a vital role in maximizing equipment performance by addressing inefficiencies through its key pillars. TPM pillars help address specific losses such as Downtimes (Impacting Availability ratio), Speed loss (Impacting Performance ratio) & Defects (Impacting Quality ratio), enabling organizations to significantly enhance OEE and transform manufacturing operations, driving efficiency, productivity, and sustained operational excellence.

Learn how to implement TPM pillars effectively with guidance from our experts.

Our customized OEE implementation approach focuses on identification of major OEE losses and selecting key tools to address major losses. Our consultants’ expertise ensures that your teams are well-equipped to maximize the benefits of OEE.

Our consultants engage all levels and functions in an organization to maximize overall equipment efficiency and empower them to identify losses and achieve higher OEE.

A vital part of our consulting is to train workers to take care of the equipment with which they work. Our TPM consultants work with your team to calculate OEE, identify losses and develop skills to implement OEE improvement strategies.

Combining OEE improvement tools with our consultants expertise helps organisations reduce losses by 50% and improve OEE by 30%.

OEE is a powerful tool for improving manufacturing performance. By systematically measuring OEE, identifying losses, and implementing targeted improvements, businesses can achieve significant benefits in terms of productivity, quality, cost, and overall equipment effectiveness.

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!