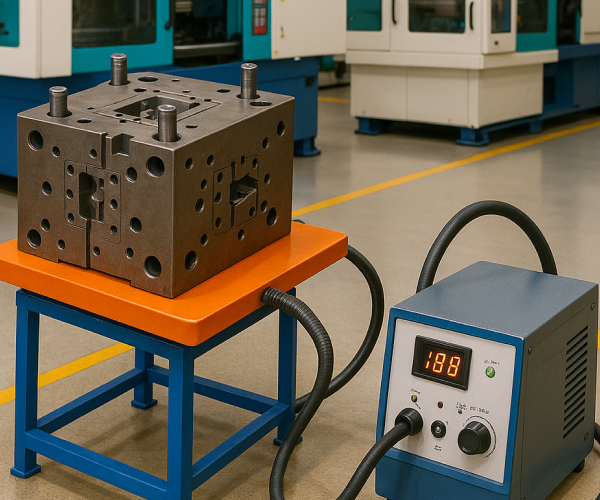

SMED stands for Single-Minute Exchange of Die, also known as Quick Changeover or Setup Time Reduction. Word single minute means single digit minute i.e. less than 10 minutes. The word “die” can be used for dies, moulds, parts, tools etc. The technique was developed by Shigeo Shingo, a renowned Japanese manufacturing expert, and is widely used in industries worldwide.

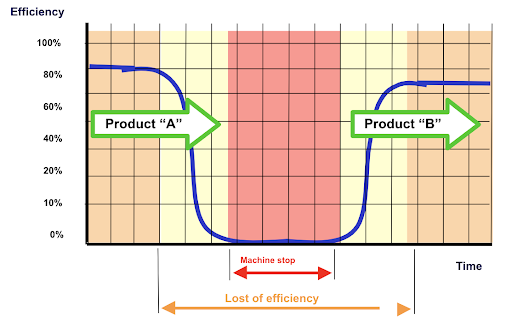

The target of SMED is to reduce time lost from the last good product to the next good product.

SMED (Single-Minute Exchange of Die) is a critical Lean tool for organizations because it drastically reduces setup and changeover times, allowing for greater flexibility, faster production response, and reduced downtime. By enabling quick transitions between products or batches—often in under 10 minutes—SMED helps companies minimize non-productive time, increase equipment utilization, and support just-in-time manufacturing. This leads to smaller lot sizes, lower inventory costs, and improved overall productivity. In highly competitive environments, SMED is essential for improving lead times, enhancing customer responsiveness, and sustaining continuous improvement across operations.

Clients

SMED Trainings conducted

SMED Workshops conducted

Reduction in Changeover time

Reduction in defects and poor quality

Increase in Operator skills for changeover

Reduction in start-up rejection

With experience across diverse industries and challenges, we deliver unparalleled insights and solutions especially designed as per the needs. For more details, contact us today!