At RIB Consulting, we focus on creating value by delivering measurable outcomes for our clients. Through a combination of tailored strategies, innovative solutions built on continuous improvement principles, with hands on learning and support, we help businesses achieve their goals and exceed expectations. Below is the summary of key results and milestones that demonstrate the impact of our work and our commitment to driving success.

Paper Manufacturing

A comprehensive multi-plant TPM assessment across yarn, towel, paper, energy and utilities identified chronic equipment and process losses, created a pillar-wise TPM roadmap, and set clear improvement targets for OEE, downtime, cost and yield across the value chain.

Textiles & Footwear

By combining TPM, Autonomous Maintenance and basic environment engineering, the textile mill stabilised packing operations, improved moisture regain and achieved significant yield and cost benefits.

Stationery & Office Supplies

A full value stream mapping exercise on the exercise-book line, combined with redesigned layout, mizusumashi routes, supermarkets, standard work and lean store controls, turned a cluttered, high-WIP environment into a controlled, flow-driven stationery value stream with clearer lead times, faster response to orders and better stock visibility.

Services

HR function boosts responsiveness and productivity through Lean Kaizen projects by eliminating non-value adding time with significant reduction in process turn around time, making HR more responsive to business needs.

Services

Finance function boosts productivity, and reduces process turnaround time and manpower costs using a structured PDCA-based Lean Kaizen methodology across two major finance processes—Payroll, and Advances & Reimbursements.

Retail

Using Lean Layout Design and Kaizen principles, RIBCON helped design a new macro-layout for the central facility that sharply reduces material movement, separates clean and dirty streams, and provides a scalable platform for future volume growth.

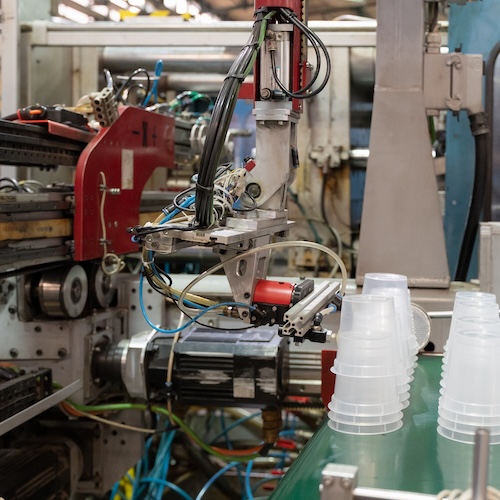

Plastics

By deploying TPM and Lean Kaizen across critical machines, the plastic plant reduced cycle times, cut trim and rejection losses, lowered power consumption per kg and improved productivity on key assembly lines without major capital investment.

Pharmaceuticals

A pharma company improved packaging inventory performance through Operational Excellence by reducing excess stock while strengthening service levels yielding significant financial gains.

Pharmaceuticals

An operational due diligence across two African pharma manufacturers benchmarked true capacity vs future demand, validated capex plans, and identified strong potential for OEE, manpower and GMP improvements before investment decisions.

Paper Manufacturing

A structured TPM programme in a paper mill, combined with deep PM analysis, improved Autonomous/Planned Maintenance and standardised shutdown practices, delivered higher OEE, lower downtime and more stable fibre supply to the machines.

Packaging

By combining TPM - Autonomous Maintenance, Root cause analysis and SMED within a structured PDCA framework, Paper Bags manufacturing firm transformed long, inconsistent print-to-print changeovers into a disciplined, fast and repeatable process.

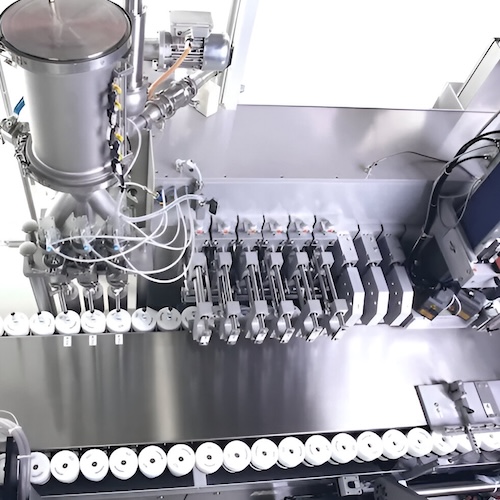

Packaging

Disposable packaging plant cuts energy cost and packing lead time in thermoforming operations

Oil and Gas

With a structured TPM “Machine Care” programme, the LPG plant reduced breakdowns, improved carousel performance and shortened truck changeover times unlocking higher throughput without major capital investment.

Metal & Mining

By applying Lean Kaizen and cellular manufacturing, the metal tin can manufacturer transformed a high-WIP, long lead-time value stream into a compact, flow-focused operation.

Metal & Mining

An aluminium mill improved quality, yield and cost through Operational Excellence, cutting overall casting rejection, reducing superficial line and temper-related defects delivering significant financial gains driven by cross-functional, data-led problem solving with shop-floor validation, experiments and standardisation.

Logistics and Transportation

Lean Kaizen enabled the logistics company to convert a high-cost, firefighting operation into a more predictable, efficient and customer-focused business.

Jewellery & Diamond

By applying Lean Kaizen to layout, material presentation and ergonomics, the plant standardised workstations, reduced operator strain and cut non–value-adding movement—improving comfort, safety and productivity without major capital investment.

HVAC & Engineering

A structured Lean Kaizen programme focused on cellular manufacturing, SMED and line balancing have helped HVAC plant significantly reduce lead time, WIP and manpower while improving flexibility and on-time delivery.

Home & Ofiice Furniture

Implementation of focussed lean kaizen workshops centered on redesigning layout and flow, stabilising methods, improving material supply, and strengthening daily controls have transformed the lines into high productivity flow-based cells.

FMCG – Personal & Home Care

By combining PM Analysis with structured root-cause elimination and daily monitoring, a leading toothpaste manufacturer significantly reduced both underfilled and overfilled material losses on critical SKUs – unlocking recurring savings in PM cost while strengthening process capability.

FMCG – Personal & Home Care

By applying Lean Kaizen across route planning, warehouse operations, truck maintenance, invoicing and regional load balancing, the company improved delivery reliability, reduced turnaround time and increased effective fleet capacity without adding trucks.

FMCG – Personal & Home Care

A global cosmetics division used Lean New Product Development, to focus its innovation strategy, strengthen customer insight and streamline launches—leading to multiple best-selling products and strong top-line growth.

FMCG – Food & Beverages

Through a focussed operational excellence approach focussing on strengthening inventory norms using lean inventory management system, FMCG company optimises raw material inventory and reduces carrying cost, generating significant savings.

FMCG – Food & Beverages

A large FMCG group in Kenya with multiple operating subsidiaries across Kenya and Uganda used Hoshin Kanri to turn its strategic intent into a clear set of priorities, align plants and functions behind those goals, and build a disciplined performance-improvement and continuous-improvement culture across the organisation.

FMCG – Food & Beverages

A strong focus on diagnostics, root cause analysis, cross-functional Rapid Improvement Workshops and Daily Work Management delivered sustained gains in yield, reliability and profitability.

Farms

By applying Lean Kaizen to brooding, feeding, flock health and cycle planning, a leading poultry business reduced cost per kg live bird, improved FCR and mortality, and increased shed utilisation without major capital investment.

Electric & Electronics

By introducing a structured TPM system, analysing product mix and capacity, and running focused SMED and manpower productivity kaizens, the industrial cable plant is able to lift OEE on critical lines, reduce changeover time and redeploy manpower more effectively.

Construction

Operational Excellence helped the client deliver construction and refurbishment projects on time and on cost while improving safety and control with zero accidents, zero equipment losses and better integration of all departments.

Chemicals & Paints

A specialty resins plant reduced batch cycle times, power and fuel consumption by running focused Lean Kaizen projects on reactors, utilities and maintenance practices. By attacking energy waste at source and simplifying operating methods, the plant freed up capacity, lowered kWh/MT and fuel cost, and improved process stability without major capital investment.

Automobile & Automotive

Automobile parts warehouse optimises stock and reduces carrying cost through Operational Excellence by tightening planning norms and replenishment discipline. This leads to significant reduction in stock for body parts, windscreens and rims, improvement in slow/non-moving norms and counter turnaround time through simpler flows and layout.

Automobile & Automotive

By running a TPM Planned Maintenance project led by the maintenance team, the plant used data-driven analysis, focused engineering changes and standardised maintenance to bring chronic faults under control resulting in higher OEE and machine reliability.

Animal Feeds

By redesigning layout and flow through Lean Kaizen and TPM, attacking chronic equipment issues and stabilising process parameters, a leading animal feed manufacturer plant significantly increased throughput, reduced losses and improved product quality.

Animal Feeds

Implementation of Autonomous Maintenance Steps 1- 3, leak elimination and operator ownership on the main air compressor significantly reduced power consumption and improved reliability of the compressed air system at Animal feed mill.

FMCG – Food & Beverages

A combination of restructuring sales teams with goal alignment and implementation of lean tools like differential selling, customer kanban, root cause analysis and daily work management significantly improved sales team productivity and market share.