Lean in Hospitals Lean methodology in healthcare emphasizes continuous improvement, patient safety, and employee engagement without overburdening individuals. It aligns hospital missions with daily practices,...

Our Latest Insights

Featured Insights

Lean Manufacturing / Kaizen- Are you Ready?

Lean Manufacturing / Kaizen- Are you Ready? Innumerable books have been written about Toyota and their lean manufacturing practices. Literally thousands of companies have tried...

Conducting Kaizen Workshops for accelerating improvement Kaizen workshops are structured team activities aimed at swiftly applying lean methods to eliminate production waste in specific shopfloor...

Understanding the use of Kamishibai Boards

Understanding the use of Kamishibai Boards Kamishibai boards offer a straightforward way to manage tasks and processes with a visual red-green card system where the...

How to identify Kaizen Projects through Kaizen assessment Kaizen means continual (step by step) improvement. there are two most common methods to identify Kaizen projects...

What is Daily Work Management and its key elements Daily Work Management is a process to gain control over plan vs actual and to bring...

Total Productive Maintenance Integration with Industry 4.0: Enhancing Operational Excellence Introduction: In the ever-evolving landscape of manufacturing, businesses are constantly striving to optimize their processes...

Using Kaizen to Reduce Costs in Poultry Farms Can continuous improvement or Kaizen actually reduce costs in Poultry Farms? Let’s find out! But first, we...

Role of Total Productive Maintenance(TPM) in Oil and Gas Industry Oil and Gas extraction activity is one of the most hazardous processes in the chemical...

Understanding the 8 pillars of TPM

Understanding the 8 pillars of TPM Even the most versatile and pocket-friendly industries are prone to many vulnerabilities. But TPM, or the Total Productive Maintenance...

Improving Manpower Productivity in Sugar Industry through Lean Manufacturing Lean Manufacturing has always been known for ‘more enhancements’ and ‘less diminutions.’, But who knew that...

How to Increase Manpower Productivity in Medical Device Manufacturing (Pharmaceutical Business) Medical Device manufacturing involves lot of manual work, thus faces challenges in manpower productivity....

Techniques to Improve OEE

Techniques to Improve OEE OEE stands for Overall Equipment Effectiveness. This is different from the efficiency of a machine which is Quantity produced in a...

Lean Implementation in Pharmaceutical industry The Indian Pharmaceutical industry is undergoing a very interesting shift; at one hand it is creating its own mark in...

Implementing 5S At Your Workplace

Implementing 5S At Your Workplace The 5S approach is a simple but powerful method for shopfloor improvement. Progressive shopfloor improvement techniques are vital for companies...

Lean Manufacturing

Lean Manufacturing Lean Manufacturingsimply means eliminating waste from manufacturing processes including waste of work in progress and finished goods inventories. What is waste? Waste is...

Kaizen Benefits and Implementation

Kaizen Benefits and Implementation “In Japanese, Kaizen means“continuous improvement”. “The word implies improvement that involves everyone—both managers and workers”. Kaizen is for any organisation (manufacturing,...

Understanding Chronic Losses in TPM

Understanding Chronic Losses in TPM Equipment failures and defects appear in two ways: as sporadic or chronic losses. Sporadic losses indicate sudden, often large deviations...

Importance of OEE in TPM

Importance of OEE in TPM Overall equipment effectiveness (OEE) is a key measurement in the improvement approach called Total Productive Maintenance (TPM). Before you begin...

TPM in Filling Lines

TPM in Filling Lines First step is to measure the OEE (Overall Equipment Effectiveness) accurately and understand the losses. All Major losses should be selected...

Benefits of 5S (Five S)

Benefits of 5S (Five S) Companies implementing 5S experience many benefits from implementing the five pillars of 5S, such as increasing product diversity, raising quality,...

What is TPM and why it is important?

What is TPM and why it is important? TPM means productive maintenance (activities in which all workers of a corporation are required to participate) and...

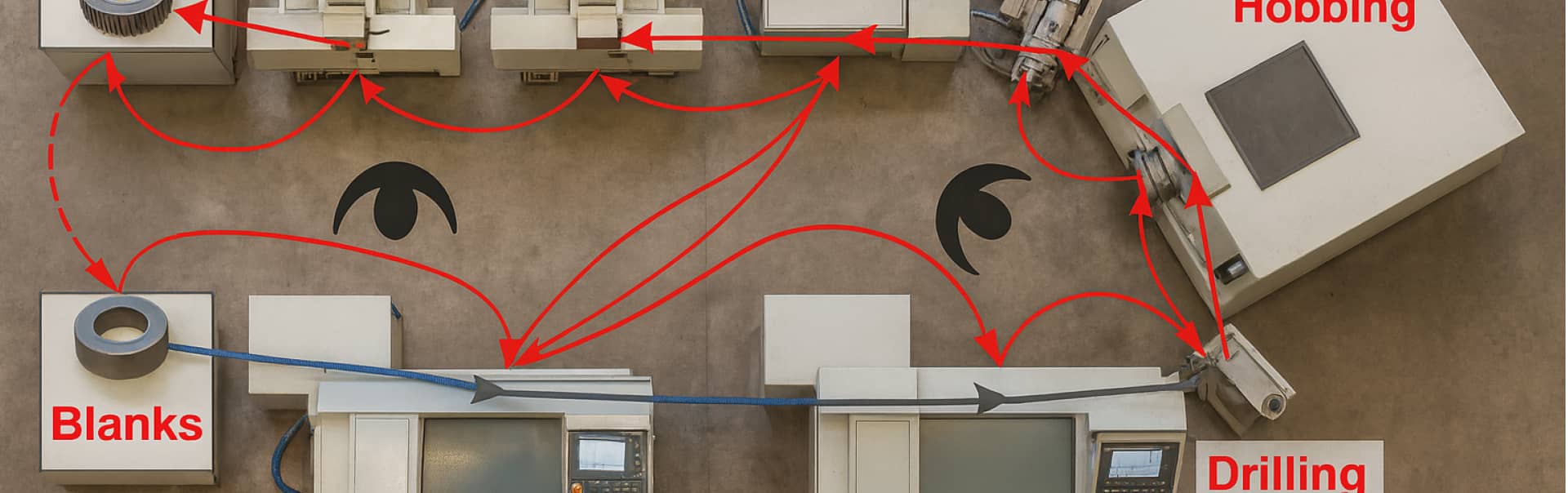

Cellular Manufacturing with Machines

Cellular Manufacturing with Machines The concept of a Cellular Manufacturing applies to processes involving machines as well as to manual assembly, with improvement opportunities of...

How to make TPM Implementation Plan

How to make TPM Implementation Plan TPM is about maximising the overall effectiveness of equipment through the people who operate and maintain that equipment. In...

Steps of Change Management

Steps of Change Management Managing change is most difficult process in any organisation and requires support of external forces and systematic Implementation of steps of...

What is Corrective & Preventive actions in Root Cause Analysis? Corrective & Preventive actions are two most common actions identified as a part of doing...

How to Implement Lean Manufacturing?

How to Implement Lean Manufacturing? Lean Manufacturing has become very popular in India & some countries in East Africa. however implementing Lean in right way...

TPM: Understanding Step 1-3 of Planned Maintenance Pillar Objective of Planned Maintenance pillar in TPM is to enhance natural life of the equipment by focuses...

Losses addressed by Kobetsu Kaizen

Losses addressed by Kobetsu Kaizen Kobetsu Kaizen (Focused Improvement) is first Pillar of Total Productive Maintenance is used to address non equipment related losses and...

Benefits of Value Stream Mapping

Benefits of Value Stream Mapping Value stream mapping also known as Material & Information flow mapping in Toyota Motors, is more than a tool to...

How to Conduct Lean Kaizen Event

How to Conduct Lean Kaizen Event | Kaizen Workshops? A Lean or Kaizen Event, also referred to as a Kaizen Workshop, Kaizen Blitz, Breakthrough Kaizen,...

What is Leader Standard Work?

What is Leader Standard Work? Standard work for leaders, the engine of lean kaizen management, is the highest leverage tool in the lean kaizen management...

Problem Solving needs simple thinking!

Problem Solving needs simple thinking! An engineer in a car manufacturing company designs a world class car. The owner is impressed with the outcome and...

What is 5S system in Kaizen

What is 5S system in Kaizen | Lean Manufacturing 5S is foundation for implementation of Lean Manufacturing / Kaizen / TPM etc. if Gemba is...

Right mindset: Key to get results from Lean Kaizen Implementation Having right mindset is ket to get results from Lean Kaizen Implementation. Leaders need to...

Autonomous Maintenance: Roles of Management, Operator and Maintenance Team TPM clearly identifies roles of Top management, Operators and Maintenance Role of Top Management in TPM...

Role of TPM in Asset Care

Role of TPM in Asset Care In the world-class manufacturing companies there is one common denominator: a firm conviction that their major assets are their...

What is Waste in Lean Manufacturing / Kaizen? Way to reduce costs through lean manufacturing or kaizen is all about identification, reduction and elimination of...

Requirements for Flow Manufacturing

Requirements for Flow Manufacturing Flow manufacturing is key component of Lean manufacturing and Toyota Production System. Flow manufacturing plays a vital role in throughput time...

TPM for Oil & Gas Industry

TPM for Oil & Gas Industry Total Productive Maintenance (TPM) has been implemented in various industries across the world. A lot of Oil & Gas...

Increase Productivity, Reduce Costs with Effective TPM Implementation The velocity of production in a manufacturing organisation depends on the uptime of the machine and process...

Top 5 Challenges in Implementing TPM

Top 5 Challenges in Implementing TPM in your organization TPM or total productivity maintenance is all about using the business resources like employees, process, and...

How good is your employee engagement in Kaizen Projects?

How do you teach your new recruits to spot waste in your process? Training the new recruits in a Manufacturing environment is a great responsibility...

Deming Award 2013 Winners

Deming Award 2013 Winners JUSE (Japanese Union of Scientists and Engineers) held Deming award ceremony on Nov 13, 2013. Following are the name of winners!...

Role Internal Kaizen Facilitator / Kaizen Coordinator To become self-sustaining in Kaizen Lean journey, an organization’s ultimate goal should be to develop a team of...

Lean Manufacturing / Kaizen- Are you Ready?

Lean Manufacturing / Kaizen- Are you Ready? Innumerable books have been written about Toyota and their lean manufacturing practices. Literally thousands of companies have tried...

Sustaining Lean Kaizen requires A Long term Philosophy In recent years there seems to be an almost maniacal rush to “Get Kaizen,” or “Get Lean”...

Key Features of Standards in Lean Kaizen

Key Features of Standards in Lean Kaizen Following standards in Kaizen is like driving a car. The driver must follow certain regulations and yet, as...

Kaizen Story / QC Story

Kaizen Story / QC Story The Kaizen story is a standardised format to record kaizen activities conducted by such small-group activities as quality circles. The...

Proactive Maintenance Management in Kaizen

Proactive Maintenance Management in Kaizen Being Proactive in Maintenance means To act before the cost of doing so increases To act before the necessity of...

Implementing Kaizen in Maintenance department Kaizen, Lean, TPM, the 80/20 rule, 5S. They are all management philosophies that can be applied to the practical aspects...

Selecting right team for Kaizen projects

Selecting right team for Kaizen projects Forming a high-performing Kaizen Team is a strategic activity, which requires a fair amount of forethought and planning. Ultimately,...

Kaizen Implementation through Kaizen Workshops In the world of continuous improvement (CI), Kaizen may perhaps be the most misunderstood concept. We’ve heard executives refer to...

Learning to see waste: Standing in a Circle exercise Learning to identify the seven types of waste (MUDA) is first challenge in implementing Lean Kaizen....

5S /5K implementation in Kaizen

5S /5K implementation in Kaizen Many companies begin their lean improvement journey by first implementing 5S, the Japanese methodology minimizing errors and mistake proofing: seiri...

Benefits of Kaizen / Lean Manufacturing

Benefits of Kaizen / Lean Manufacturing What is the benefits of implementing Kaizen and economic rationale for pursuing lean manufacturing. Much of the Kaizen Lean...

Root Cause Analysis in Kaizen Lean Why Why Analysis or 5 Whys is a well-known root cause analysis technique that originated at Toyota and has...

History of Kaizen / Lean thinking

History of Kaizen / Lean thinking The story of Kaizen and Lean thinking began in the early 1900s in Japan with the Toyoda family business,...

Implementing TPM Kaizen to Improve Plant OEE

Implementing TPM Kaizen to Improve Plant OEE Improving Plant OEE and reducing downtime is biggest concern most of the organisation have. Here are steps on...

RIB Consulting Client “Strongpak” in Zambia wins the Gold Award in Manufacturing Sector The 4th National KAIZEN Conference took place at the Mulungushi International Conference...