Lean Kaizen in Production | Kaizen in Manufacturing

What would an increase in productivity of 25% mean to your organisation? How much time and money would be saved if scrap levels were reduced by 30%? How many customers would be happy if your delivery performance improved by 25%? How much cash would be freed up if you could reduce your inventory by 30%? What could you do if one- third of your space gets free?

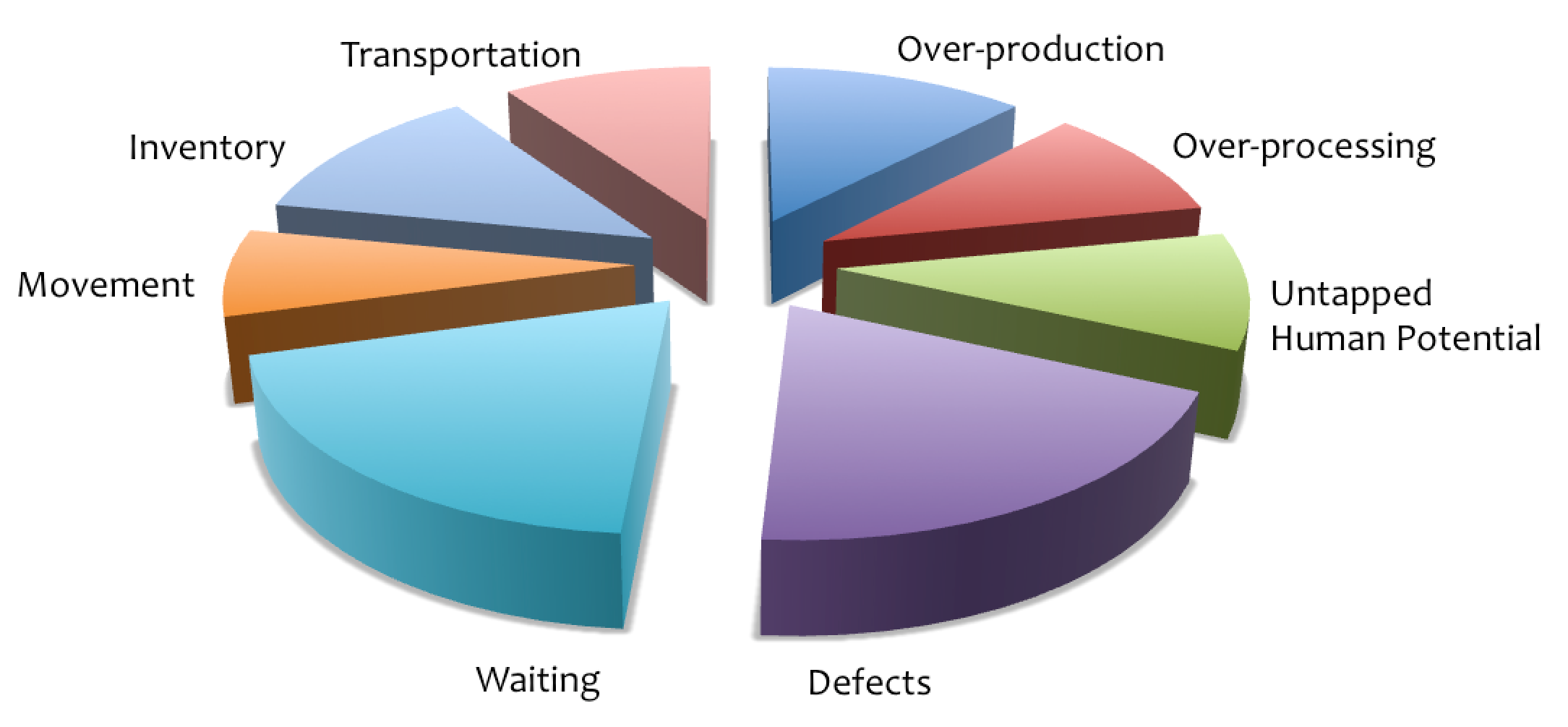

It will be much more impactfull leading to Higher Profits and Increased Business by implementing Lean Manufacturing tools. Lean Kaizen in Production department creates Just in Time flow at the pull of the customer by eliminating key wastes in your processes ie Transport, Inventory, Motion, Waiting, Over-processing, Over production and Defects.

Implementing Lean Kaizen tools effectively customised to the needs of your business can result to:

Higher efficiencies, more output per man hour

Quality performance, fewer defects and rework

Fewer Machine and Process Breakdowns

Less Cycle time and throughput time

Lower levels of Inventory

Lower Space Utilisation

Improved delivery performance

We are global kaizen manufacturing consultants offering Kaizen consultancy services across manufacturing industries across India including Delhi, Noida, Gurgaon, Mumbai, Chennai, Bangalore, Ahmedabad, and Punjab. Make your manufacturing unit productive and cost effective in Lean Kaizen way with a team of our technical experts having in-depth knowledge and experience across industries. Get Lean Kaizen expert today!