Lean Six Sigma Yellow Belt Certification Online Training

Enroll Now

24 hours of training

Facilitator Led Online Training facilitated by Lean Six Sigma Experts

Online Access to course content

Online Exam

Case studies

Lean Six Sigma Yellow Belt Course completion certificate

What you’ll learn?

Preparation of mindset for Lean journey in an organization and dealing with resistance

Lean Management Principles & 7 Wastes

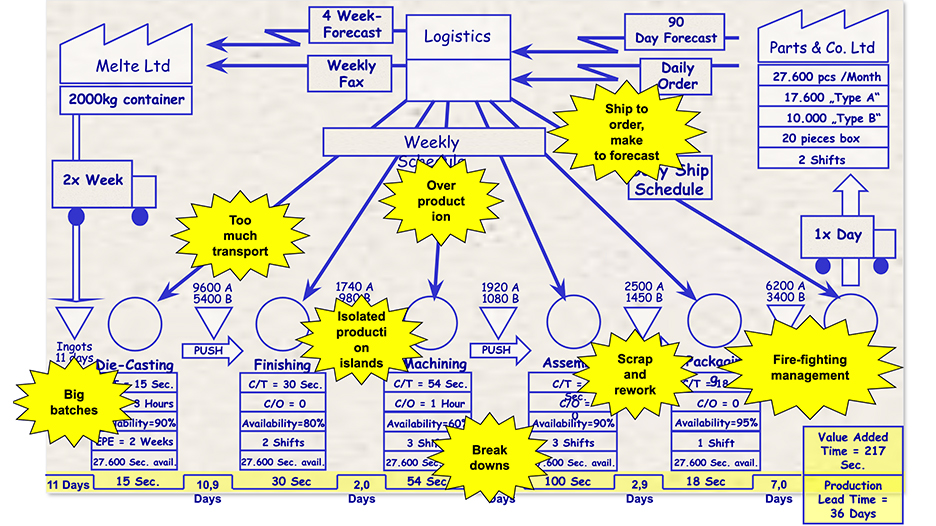

Value Stream Mapping, Creating Continuous Flow & Pull System

Statistical Process Control, Basic Quality Tools

DMAIC & Key Six Sigma Tools

Who should attend?

Lean Six Sigma Yellow Belt Certification training course is meant for any professional seeking career growth in Lean or seeking hands-on experience working with Six Sigma tools and techniques. There is no eligibility criteria for enrolling into Lean Six Sigma Yellow Belt Certification course.

- Understanding Paradigms and Paradigm shift

- Discovering Organisational Paradigms

- Techniques and steps of changing paradigms

- Paradigm shift examples and success stories

- Steps of dealing with resistance

- Key principles of Lean Manufaturing

- In-depth understanding of 7 wastes (MUDA)

- Techniques to identify 7 Wastes

- Improvement Methodology: PDCA /li>

- Value Stream Mapping: Learn to identify waste with a systematic approach

- Current State Value Stream Mapping

- Principles of Future State Value Stream Mapping

- Key Tools for material and information flow in Manufacturing

- Understanding Cycle time & Takt Time

- Steps of doing Line Balancing

- Principles of Layout Design

- Cellular Manufacturing & Steps of creating Cells

- Changeover times reduction using SMED

- What is Six Sigma & Key Benefits of Six Sigma

- DMAIC Methdology

- Voice of Customer, Project definition & Ranking

- Create structure & system for sustenance of results: Managing Daily and Weekly reviews, and managing steering committee reviews

- Process Mapping

- Understanding Variation

- Process Capability

- Sampling & Measurement Systems

- Data Collection & Planning Tools

- Calculating Process Six Sigma Level

- Problem Solving & 7 Basic Quality Tools

- Mistake Proofing

- Assessing the Results

- Process Control Plan

- Establishing Statistical Process Control

- Project Review Mechanism

RIBCON Training Advantage

Combination of educational presentations and case studies

Productive in-session assignments and participants collaboration to provide actionable learning

Training by senior consultants with in-depth knowledge and hands-on experience across various industry sectors

About the Instructors

Our instructors are Lean Six Sigma experts who have worked for more than 150 companies across various industries from past 15 years. Our team has conducted over 400 Lean Six Sigma workshops & Trainings and have delivered significant results in cost reduction and quality improvement

Client Testimonials

Become Certified Lean Six Sigma Expert

RIBCON conducts an online exam at the end of Lean Six Sigma training program. You need to score 60% to receive a course completion certificate. Enroll today and become Lean Six Sigma Expert