Manpower Productivity Improvement

One of the key elements to improve productivity is to reduce MUDA ie waste in any process or workflow. RIB introduced Kaizen tools in lot of companies to eliminate issues that impact productivity:

Waiting time between work processes

Material Movement between processes

Non-value adding activities by employees

Manual workflows

Imbalanced Cycle times

RIB clients have experienced significant improvement in productivity by 30%-40% & managed to sustain the same with implementation of following tools:

Line Balancing: A Lean tool that uses right amount of people to make the right amount of product within desired time (Customer demand rate or TAKT Time). It helps to reduce time required to make product or to deliver service & also reduces manpower required in the process.

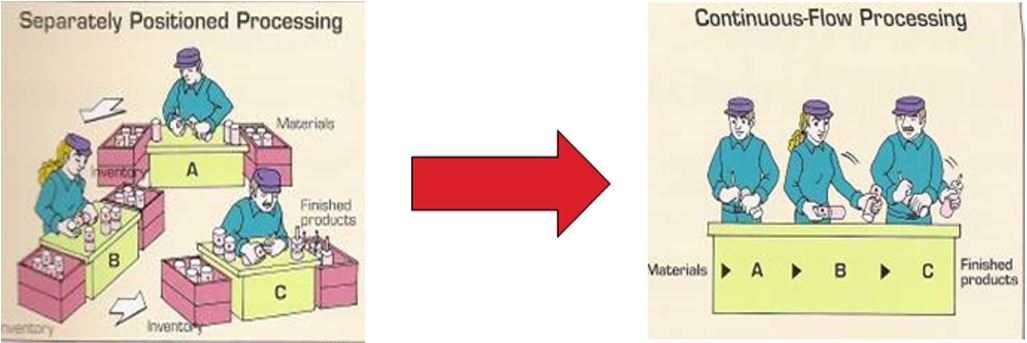

Cellular Manufacturing: An approach where equipment & workstations are arranged closely to facilitate continuous flow production. It helps reduce set-up time, flow time & response time to customer orders.

Standard Work: It’s a tool that helps setting best, safest & easiest way to perform the work practices to set baseline for continuous improvement & eliminating waste. Without standard work there can be no improvement and there can be no standard work without improvement.

It’s very simple! We are here to help you begin your journey with Kaizen today.

View Productivity Improvement Kaizen journey of India’s leading plastic component manufacturer >