Value Stream Mapping (VSM) has increasingly become a popular tool in Lean or Kaizen Implementation. Value stream Mapping has been used by Toyota Motors for many years to map material and information flow to understand where waste is in the Process. Identification of MUDAor Waste is the first step of implementing Kaizen or Lean.

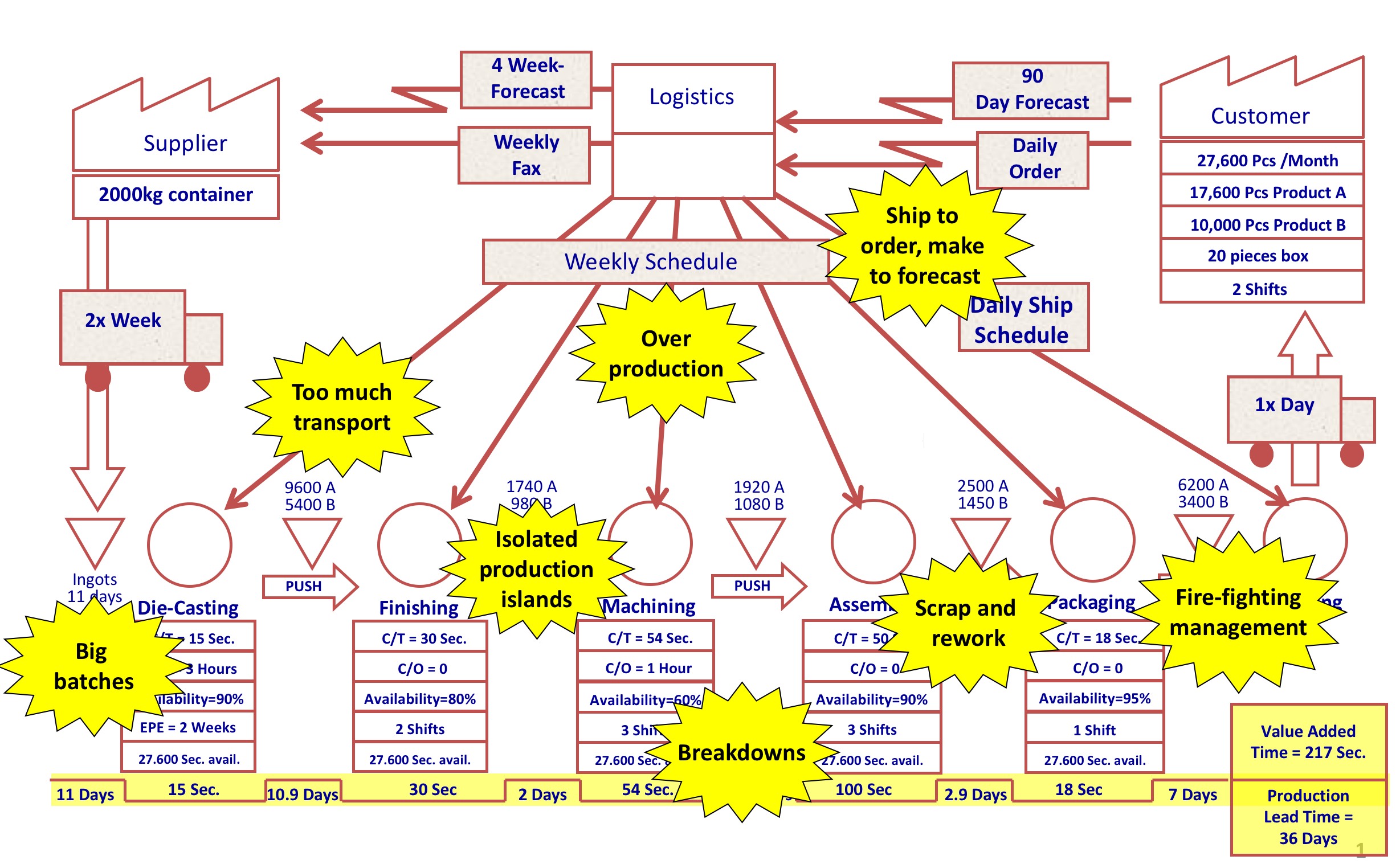

Value Stream Mapping tool was created as a tool for Learning to see waste or MUDA. Value scream is all the actions (both value added and non-value added) currently required co bring a product through the main flows essential to every product: the production flow from raw material into the arms of the customer, and the design flow from concept to launch. Value Stream mapping helps to see the big picture, not just individual processes, and improving the whole, not just optimizing the parts of the process.

Why does your business needs Value Stream Mapping?

- VSM helps you visualize more than just the single-process level, i.e. moulding, assembly, packing, etc., in production. You can see the flow of entire operations

- VSM shows the linkage between the information flow and the material flow.

- VSM helps you see more than waste. Mapping helps you see the sources of waste in your value stream.

- VSM ties together lean or Kaizen concepts and techniques, which helps you avoid falling in trap of implementing the popular Lean Tools

- VSM forms the basis of creating Kaizen implementation plan.

Value stream maps become a blueprint for lean implementation and as important is for your business as Blueprint is before building a house.

It is much more useful than quantitative tools and layout diagrams that produce a tally of non-value-added steps, lead time, distance traveled, the amount of inventory, and so on. Value stream mapping is a qualitative tool by which you describe in detail how your facility should operate in order to create flow. Numbers are good for creating a sense of urgency or as before/after measures. Value stream mapping is good for describing what you are actually going to do to affect those numbers.

RIB Consulting has helped several organisation to effectively implement Value stream Mapping and creating Future state maps and Kaizen Implementation plan that will make a difference in your bottom line. RIB Consulting is leading Value Stream Consultant in India, Kenya & UAE. We have implemented Value stream mapping in Automotive, Metal, FMCG, Horticulture, Plastics & Packaging and several other industries.