TPM Certification – Become expert on TPM

Enquire Now

16 hours of training

8 Days Training by TPM Expert

Access to course content

Case Studies and Assignments

Online exam

TPM course completion certificate

What you’ll learn?

Grasping and practicing the fundamentals of Total Productive Maintenance

How to extend the life cycle of assets using TPM pillars

Identification and steps of reducing OEE losses

Arriving at the root cause of problems to stop them from reoccurring in the future

Using Autonomous Maintenance to increase ownership and responsibility of the operators for their work process

Latest Preventive Maintenance methods to increase reliability and availability of machinery

Who is it for?

TPM certification training course is meant for any professional seeking career growth in production, maintenance, operations and engineering department or seeking hands-on experience working with TPM tools and techniques. This training is intended for all who is associated with the production system, from engineers and supervisors to shop floor workers, maintenance personnel and support staff. There is no eligibility criteria for enrolling into TPM certification course.

- What is TPM

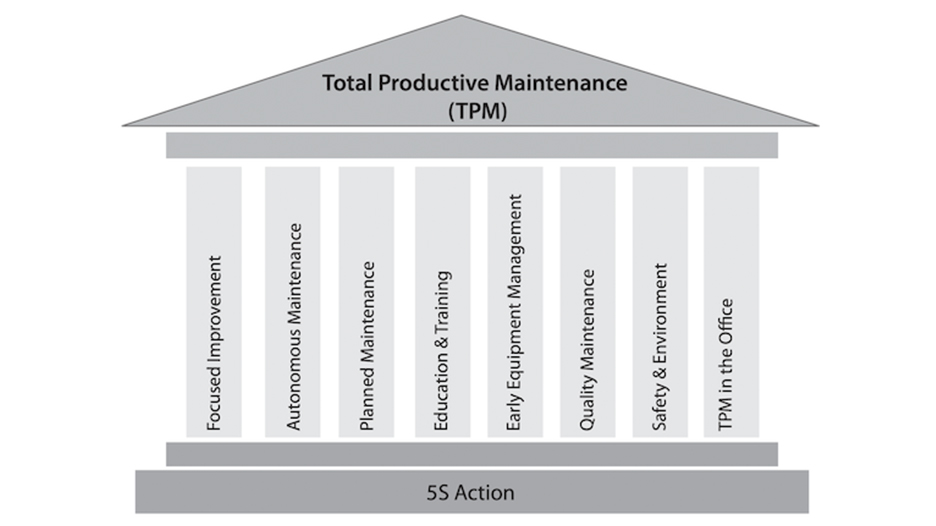

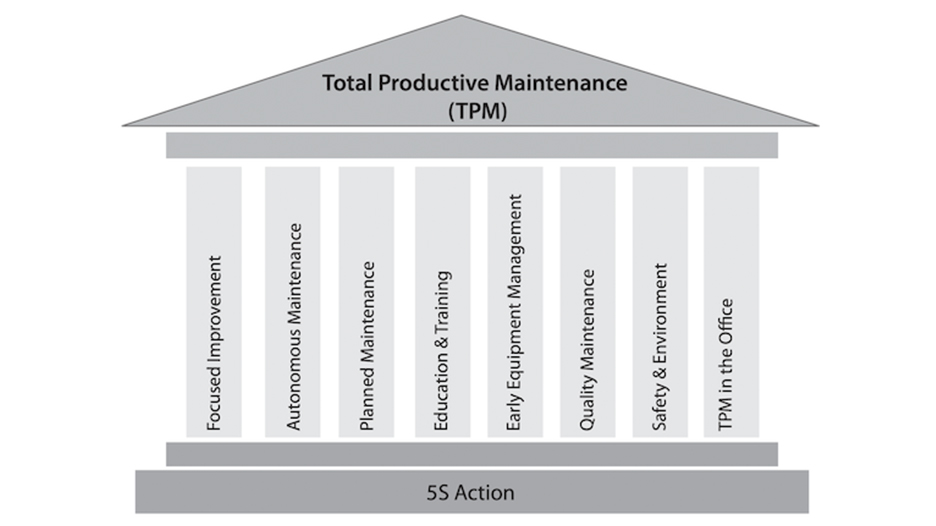

- 8 Pillars of TPM

- Benefits of TPM

- TPM Success Stories

- Summary and Quiz

- Understanding Overall Equipment Effectiveness (OEE)

- Calculating OEE losses

- Understanding Chronic and Sporadic losses

- OEE loss calculation Exercise

- Summary and Quiz

- Understanding concept of Root Cause Analysis

- Steps of Root Cause Analysis – Pareto/Cause-and-Effect Diagram, Gemba validation, and Why Why analysis

- Examples and Case Studies

- Summary and Quiz

- 7 Steps of Autonomous Maintenance

- Key preparations for successful implementation

- Methodology of Implementing AM Step 1-3

- Case Studies explaining the use and benefits of Autonomous Maintenance

- Support to Autonomous Maintenance

- Evaluation of equipment Failure/ Breakdown status (Equipment Control Ledger and equipment ranking)

- Time based maintenance (TBM) and Condition based maintenance (CBM

- Spare Parts Management

- Examples and Case Studies

- Understanding concept & Benefits of SMED

- Steps of SMED to reduce Changeover time

- How to Implement SMED in your organisation

- Sustaining the SMED results

- Practical examples & Case Studies

RIBCON Training Advantage

- Combination of educational presentations and case studies

- Productive in-session assignments and participants collaboration to provide actionable learning

- Training by senior consultants with in-depth knowledge and hands-on experience across various industry sectors

Opportunity to get work assignments of TPM implementation

About the Instructors

Our instructors are TPM experts and have been trained in Japan and has extensive experience of working on TPM Projects with Japanese Senseis. Our Trainers have implemented TPM Projects at more than 150 companies across various industries from past 15 years. Our team has conducted over 250 TPM workshops & Trainings on Preventive Maintenance, 5S, Lean Manufacturing, Just-In-Time, Total Productive Maintenance (TPM), Total Quality Management, Total Flow Management (TFM), Daily Work Management, and Hoshin Kanri.

Client Testimonials

Get TPM Certified

RIBCON conducts an online exam with one project completion at the end of TPM Certification Training program. You need to score 60% to receive a course completion certificate. Enroll today and become TPM expert.