What is the benefits of implementing Kaizen and economic rationale for pursuing lean manufacturing. Much of the Kaizen Lean literature is concerned with the nuts and bolts of lean, and the economics of lean are somewhat less publicized.

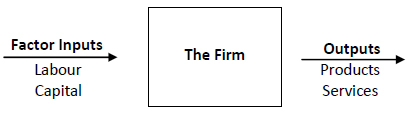

Firms employ capital and labor to transform their raw materials into their output goods and services. The inputs of capital and labor are the so-called factors of production. Through a simple thought experiment, we can think of the firm as a large production process that takes the factor inputs and uses them to transform raw materials into output products and services (see figure 1). Note that this model applies equally well to non manufacturing firms, although these firms may transform things other than raw materials into outputs:

Figure 1: Factor inputs used to transform raw materials into output products and services

A firm’s production function describes how much output can be produced with a given combination of inputs. If we consider that the goal of a firm is to maximize its profitability, firms should always strive to be efficient in their operations. In economic terms, efficiency is thought of in two ways:

Technical (or technological) efficiency. Technical efficiency is achieving the maximum output possible from a given set of inputs. If a process is producing the maximum amount possible, given its labor and capital, then that process may be said to be technically efficient.

Economic efficiency. Economic efficiency is concerned with more than just technical efficiency. Economic efficiency is concerned with allocating resources wisely so as to minimize the costs associated with using a given combination of inputs to produce a given output. If a firm’s goal is to maximize its profit, then the firm should consider which technically efficient processes best achieves that objective. An economically efficient production system is one that best allocates resources to produce output at the least cost.

Achieving improvements in technical efficiency requires improving the technical means of production. These improvements may consist of changes to the methods and technologies used in production so as to obtain the greatest output from a given set of inputs. Lean production has a role to play here as many of techniques and tools of lean are designed to reduce or eliminate the waste and nonvalue-adding activity which prevents a process from realizing the maximum output from a given set of inputs.

Economic or allocating efficiency, on the other hand, is essentially a strategic question. What businesses should the firm be in? What markets and customer groups should it be serving? What products and services should be supplied and in what quantities? What inputs does the firm require, and how can the cost of these be minimized? Which capabilities and processes are required to serve customers, and how should these be designed and configured? These and other questions are strategic in nature and determine in large measure how a firm will allocate its resources so as to be economically efficient in its chosen business.

For a firm, the issue of profit maximization seems, on the surface, straightforward. Profit is given by the following simple equation: P = TR – TC, where P is a firm’s profit, TR is the firm’s total revenues, and TC is the firm’s total costs. Profit maximization is not simply about maximizing revenues and minimizing costs. Rather, it is an optimization exercise that recognizes the interdependency between revenues and costs: As a firm increases its output to sell more and increase revenues, it also increases costs. The key question in this interdependent relationship is what happens at the margin—i.e., how do revenues and costs behave with each additional unit of production? For most firms, profits are maximized when marginal revenues equal marginal costs.