Way to reduce costs through lean manufacturing or kaizen is all about identification, reduction and elimination of 3 Mu’s. The 3 Mu’s are the three main types of waste that Kaizen teams target in their improvement activities. Each of these types has aJapanese name that begins with the syllable mu. They are defined as follows:

Waste (Muda) = Capacity exceeds the load. This is a waste of capacity. Muda is any form of activities where physical shape or chemical properties of product or service does not change as per customer requirement or any activities for which customer is not willing to pay for. Lets take a simple example to undestand Muda. You walk into a restaurant and you have to wait for seat, once you get seat, you wait for menu, once you go through menu then you wait for some one to take order, once order is taken you wait another 15-20 mins for food to come. Once food arrives, it take up to 30 mins to comfortably enjoy your food, then you again wait for bill. Only value adding activity here is getting the righ qualtiy of food you ordered rest all activities are waste. If taste of food is not good even that is Muda.

Inconsistency (mura) = Capacity sometimes exceeds the load and the load sometimes exceeds the capacity. Mura means variation and is generally caused by non standard work and MUDA. For example some times right quality product is produced and sometimes not. Sometime production targets are met and sometimes not.

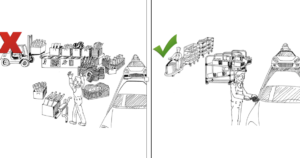

Irrationality (muri) = Load exceeds capacity. Muri means overload or stress on machines or manpower. For example overheating of machines or overworking of manpower will result in breakdown.

To reduce or eliminate 3 Mu’s first thing you must do is learn to identify them. Like 90% of an iceberg is hidden under water, same way waste is hidden. There are total 7 types of wastes and there are different types of kaizen tools to identify, reduce or eliminate them