Standard work for leaders, the engine of lean kaizen management, is the highest leverage tool in the lean kaizen management system. Leader standard work provides a structure and routine that helps leaders shift from a sole focus on results to a dual focus on process plus results. This change in focus is crucial to the success of a lean operation. Moreover, it is perhaps the most difficult thing to accomplish in a leader’s personal conversion from batch and queue to lean thinking. Leader standard work aids this conversion by translating the focus on process, an abstract concept, into concrete expectations for the leader’s own specific job performance. Just as standard work elements in a production workstation provide a clear and unambiguous statement of expectations, the same is true of standard work for leaders.

Leaders’ work is rarely timed this closely. Even so, it is important to pay attention to the total work content called for in leaders’ standard work to be sure they can perform it effectively and thoroughly. Leaders’ standard work includes coverage of visual controls and executing the daily accountability process. Follow leader standard work and you maintain the principal elements of the lean management system. Maintain the lean management system, and you maintain the health of your lean production system and enjoy its results.

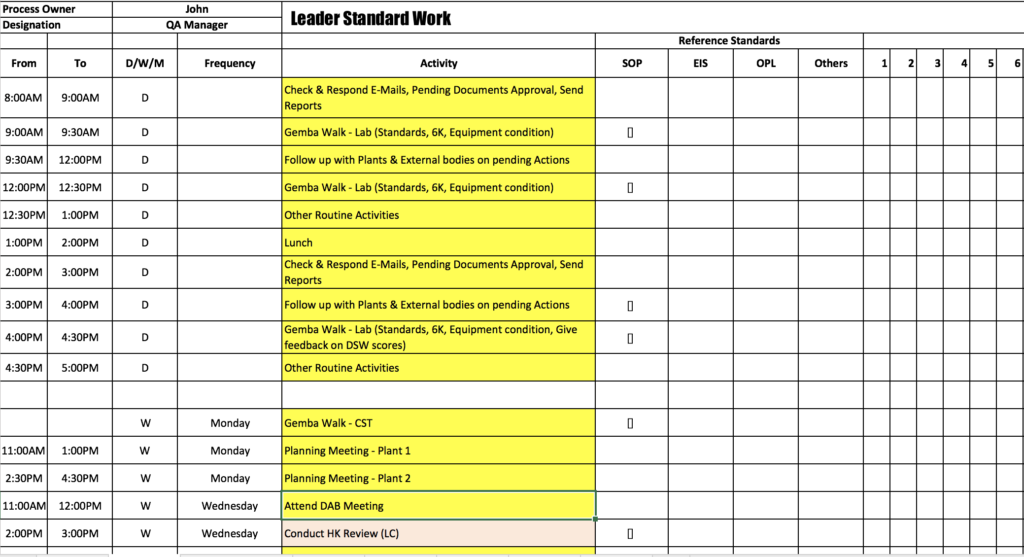

Leader standard work includes some tasks that are specifically sequenced to happen at indicated times. Others occur once a day, once a week, or as the need arises. Some tasks repeat several times every day. Leaders’ standard work differs markedly from operator standard work in one important respect.Leaders should have their standard work with them virtually all the time, whether on a clipboard, printed on a card, in a daily planner, or in a digital device. The leader should note completion of the indicated tasks on the standard work form.

With leader standard work, the lean management system becomes process-dependent, not person-dependent. One benefit is continuity of basic practices across changes in incumbents, which minimizes variability that might destabilize the production process. But more important is a second benefit is that leader standard work quickly allows an organization to raise the game of the existing leadership staff, or highlight those unable to make the transition. Leader standard work does this by presenting a clearly stated recipe—the standards for expected behaviors for leaders in a newly lean environment.