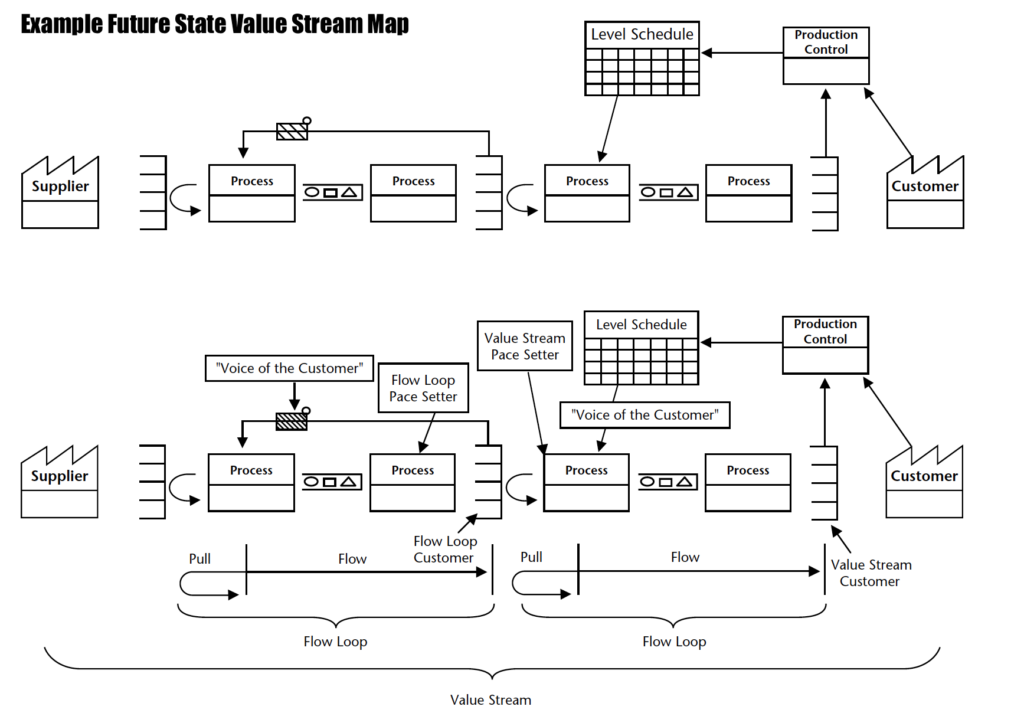

Value stream mapping also known as Material & Information flow mapping in Toyota Motors, is more than a tool to draw pictures that highlight waste. It helps us see linked chains of processes and create Future state of a Lean value steam. Key philosophy of Value stream mapping is how to approach improvement and to improve overall material and information flow.

Value Stream maps also provide a “common language” and understanding so that everyone has the same vision for Lean or Kaizen Implementation. Like a road map, the value stream mapping tool shows the road for the Kaizen or Lean journey, but it is only a guide. It does not detail what you will find along the way in your Kaizen journey. You must have a thorough understanding of the basic concepts and how to create processes that adhere to them. This is when it is very helpful to have someone who has previously made the journey. They not only know where they’re going, but they can save countless hours otherwise wasted by taking wrong turns!

Some of the common objectives used from value stream mapping are:

- Short lead-time from customer order to completion and delivery of the product.

- Connected processes with continuous flow and pull of materials.

- Simplified information flow within the value stream that comes from internal customers (the following process).

- A clear awareness of the customer requirement (the “voice of the customer”). In a pull environment, the customer (next operation) dictates what is done and when. The voice of the customer should provide: Required rate (TAKT time), Required volume (quantity), Required model mix and Required sequence of production