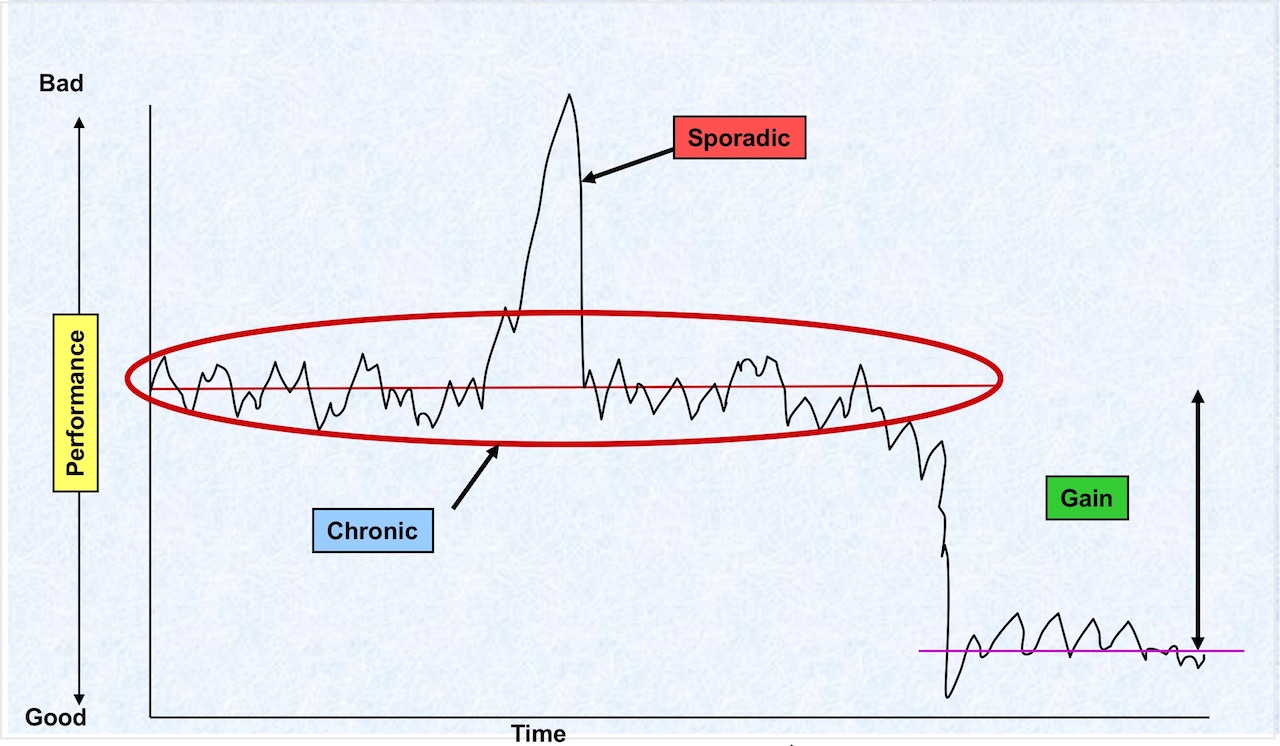

Equipment failures and defects appear in two ways: as sporadic or chronic losses. Sporadic losses indicate sudden, often large deviations from the norm (current performance and quality levels). Chronic losses, on the other hand, indicate smaller, frequent deviations that gradually have been accepted as normal.

Sporadic losses, as the name implies, occur suddenly and infrequently. Typically, they result from a single cause that is relatively easy to identify. Also, because cause-and-effect relationships in sporadic losses are fairly clear, corrective measures are usually easy to formulate. For example, quality defects may arise when a jig has become abraded to a point where it no longer supports the required precision. Or a spindle may suddenly vibrate excessively, causing unacceptable dimensional variations in the product.

Chronic Losses on other hand, live up to their name by resisting a wide variety of corrective measures. Chronic losses require Innovative & Breakthrough measures that restore the mechanism or component to its original state. In nearly every cause, countermeasures done using Traditional approach for Chronic losses may bring temporary relief to the problem.

There are two types of Chronic loss:

- The problem is produced by a single cause, but the cause varies from one occurrence to the next: Suppose for a given problem there are ten potential causes, A through J. Each time the problem occurs, the cause is different. Sometimes it may be A, sometimes C, or D, and so on. Consequently, measures focused on only one specific cause (A, for example) cannot control the problem.

- The problem is produced by a combination of causes, which also varies from one occurrence to the next: In some cases a combination of multiple and overlapping causes generates the problem. To make matters worse, each time the problem occurs, a different combination of factors may be involved. Today it may be factors A, B, and C; tomorrow A, C, G, and H.

Chronic losses persist for another reason. Even when people understand the nature of chronic loss, they continue to use a flawed problem-solving approach. Three types of errors are common in chronic loss analysis:

- Phenomena are insufficiently stratified and analyzed.

- Some factors related to individual phenomena are overlooked.

- Abnormalities hidden in individual factors are not addressed

Dealing with Chronic losses require advance level technique in Total Productive Maintenance (TPM). Technique is known as PM (Phenomenon Mechanism) Analysis.